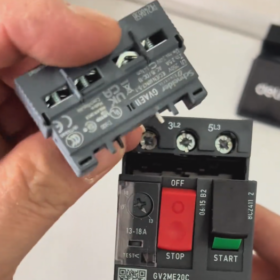

شنايدر موتور كاتب GV2ME20C

بداية محرك شنايدر GV2ME20C هو منتج ضمن سلسلة TeSys Deca GV2, مصممة في المقام الأول لحماية والتحكم في المحركات الكهربائية ثلاثية الطور. وفيما يلي مقدمة مفصلة لها:

المعلمات الأساسية

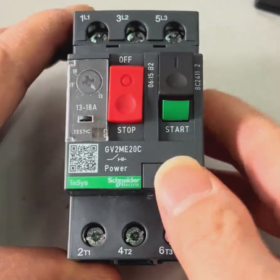

التصنيف الحالي: 18أ, مع نطاق إعداد الحماية من الحمل الزائد الحراري من 13 إلى 18 أمبير

رقم القطب: 3ص

نوع الجهد: تكييف, 50/60هرتز

الجهد المقنن: جهد التشغيل المقدر وجهد العزل 690 فولت تيار متردد; النبض المقنن يتحمل الجهد 6 كيلو فولت

تيار الرحلة المغناطيسي: 223أ

أبعاد: 89ملم × 44.5 ملم × 78.2 ملم

وزن: 0.26كجم

ميزات المنتج

وظائف الحماية: مجهزة بوحدة رحلة حرارية مغناطيسية, يوفر حماية من الحمل الزائد وقصر الدائرة للمحركات, جنبا إلى جنب مع القدرة على حماية فشل المرحلة.

طريقة التركيب: يدعم تركيب السكك الحديدية DIN, السماح بالتركيب الرأسي أو الأفقي للراحة وتوفير المساحة.

طريقة التشغيل: يتم التحكم فيه عن طريق الضغط على زر لبدء التشغيل وإيقاف المحركات يدويًا.

الشهادات الشاملة: يتوافق مع المعايير ذات الصلة مثل EN/IEC 60947, ويحمل شهادات بما في ذلك 3C, م, أول, ووكالة الفضاء الكندية, ضمان سلامة وموثوقية ممتازة.

عمر الخدمة الميكانيكية: يتميز بعمر خدمة ميكانيكي يبلغ 100,000 دورات, تلبية متطلبات التشغيل على المدى الطويل.

مجالات التطبيق

مناسبة للصناعات مثل المنتجات الغذائية/الزراعية, التعبئة والتغليف / صناعة الورق / الطباعة, ومعالجة الصلب/المعادن, توفير حماية وتحكم موثوقين للمحركات الكهربائية.

مبدأ عمل شنايدر موتور ستارتر GV2ME20C

- تحديد موضع المنتج والهيكل الأساسي

GV2ME20C عبارة عن مشغل يدوي وحامي للمحرك في سلسلة TeSys Deca من شنايدر, دمج وظائف التحكم والحماية. إنها مناسبة للتحكم في التشغيل والإيقاف والحماية الكهربائية المتعددة للمحركات غير المتزامنة ثلاثية الطور.

الهيكل الأساسي:

3-قاطع الدائرة الحرارية المغناطيسية القطب (3ص) مع تيار مقنن 18A ونطاق إعداد الحماية الحرارية من 13-18A

لوحة التشغيل بضغطة زر (ابدأ/توقف)

وحدة رحلة حرارية مغناطيسية مدمجة (شريط ثنائي المعدن + لفائف كهرومغناطيسية)

جهات الاتصال المساعدة وجهاز إشارة الرحلة

قاعدة تركيب السكك الحديدية DIN

- نظرة عامة على مبدأ العمل

آلية الحماية المزدوجة: تجمع وحدة الرحلة الحرارية المغناطيسية بين خاصيتين للحماية لتحقيق حماية شاملة للمحرك:

الحماية الحرارية (حماية الزائد): يستخدم الشريط ثنائي المعدن لاستشعار ارتفاع درجة الحرارة الناجم عن التيار الزائد, تنفيذ التعثر المؤجل معكوس الوقت.

الحماية المغناطيسية (حماية ماس كهربائى): يستخدم الملف الكهرومغناطيسي للكشف عن تيارات الدائرة القصيرة الكبيرة, تمكين التعثر لحظية.

ثالثا. آلية العمل التفصيلية

- حالة التشغيل العادية

يتم توصيل الطاقة إلى المحطات ثلاثية الطور (L1/L2/L3) وتنتقل إلى المحرك (T1/T2/T3) عبر جهات الاتصال الرئيسية.

اضغط على زر ابدأ; يحافظ المزلاج الميكانيكي على إغلاق جهات الاتصال الرئيسية, ويبدأ المحرك في العمل.

عندما يبقى التيار ضمن النطاق المقنن, لا يتم تنشيط العنصر الحراري ولا الملف الكهرومغناطيسي.

- مبدأ العمل للحماية من التحميل الزائد (الحماية الحرارية)

المكون الأساسي: شريط ثنائي المعدن (يتكون من معدنين لهما معاملات تمدد حراري مختلفة مرتبطة ببعضها البعض)

| منصة | عملية العمل |

| ارتفاع غير طبيعي للتيار | الحمل الزائد للمحرك → يتجاوز التيار نطاق الإعداد → تزداد درجة حرارة العنصر الحراري |

| تراكم التشوه | ينحني الشريط ثنائي المعدن ويتشوه بسبب اختلافات درجات الحرارة |

| إطلاق الرحلة | يصل التشوه إلى الحد الأدنى ← يدفع آلية الرحلة ← يحرر المزلاج ← تفتح جهات الاتصال الرئيسية |

| خاصية الحماية | خاصية الزمن العكسي: كلما كان الحمل الزائد أكثر خطورة, كلما كان وقت التعثر أقصر (مطابقة الخصائص الحرارية للمحرك) |

طريقة الإعداد: اضبط الموضع الأولي للشريط ثنائي المعدن عبر مقبض اللوحة الأمامية لضبط قيمة تيار الحماية (13-18أ).

- مبدأ العمل لحماية ماس كهربائى (الحماية المغناطيسية)

المكون الأساسي: ملف الرحلة الكهرومغناطيسي + آلية حديد التسليح

في حالة حدوث ماس كهربائي → يرتفع التيار بشكل حاد (≥13 مرة التصنيف الحالي, حوالي 223 أ) → يولّد الملف مجالًا مغناطيسيًا قويًا.

يتغلب جذب المجال المغناطيسي على مقاومة الزنبرك ← يسحب عضو الإنتاج بسرعة ← يضرب ذراع الرحلة.

يتم تحرير المزلاج ← تفتح جهات الاتصال الرئيسية على الفور (وقت الاستجابة < 10آنسة) → يتم قطع تيار الدائرة القصيرة.

- مبدأ حماية فشل المرحلة

يراقب توازن التيارات ثلاثية الطور. عندما تكون أي مرحلة مفقودة أو غير متوازنة بشدة:

يتجاوز فرق التيار ثلاثي الطور العتبة المحددة ← يتم تنشيط العنصر الحراري (بسبب زيادة التيار في المراحل غير الخطأ) → يثير التعثر.

وقت استجابة الحماية < 1 ثانية, منع احتراق المحرك الناجم عن التشغيل أحادي الطور.

- وظائف الحماية الأخرى

حماية الجهد المنخفض: عندما ينخفض جهد مصدر الطاقة إلى أقل من ذلك تقريبًا 70% من القيمة المقدرة, يتم تنشيط وحدة رحلة الجهد المنخفض لقطع مصدر الطاقة.

رحلة التحويلة: يمكن توصيله بإشارة تحكم خارجية (على سبيل المثال, بلك) لتحقيق الاغلاق في حالات الطوارئ عن بعد.

التعشيق الميكانيكي: الميزات أ “انقطاع التيار الكهربائي لفتح الباب” وظيفة لضمان سلامة الصيانة; يمكن قفل أزرار التشغيل لمنع سوء التشغيل.

- طرق التشغيل والتحكم

- التحكم اليدوي

يبدأ: اضغط على زر البدء ← يقوم المزلاج الميكانيكي بقفل جهات الاتصال ← يتم تنشيط المحرك وتشغيله.

قف: اضغط على زر الإيقاف ← تحرير المزلاج ← فتح جهات الاتصال ← يتم إلغاء تنشيط المحرك.

إعادة تعيين الخطأ: إعادة الضبط اليدوي (اضغط على زر إعادة الضبط) مطلوب بعد التعثر قبل إعادة التشغيل.

- التحكم عن بعد (عبر المكونات الخارجية)

يتم استخدامه مع المقاولين لتحقيق التحكم في التشغيل والإيقاف عن بعد عبر PLC أو أنظمة التحكم.

يمكن لوظيفة رحلة التحويلة استقبال إشارات خارجية لإيقاف التشغيل في حالات الطوارئ.

- ملخص خصائص الحماية

| نوع الحماية | حالة الزناد | خاصية الاستجابة | وظيفة الحماية |

| الزائد | 1.05~ 1.5 مرة التصنيف الحالي | معكوس الوقت (عدة ثوان إلى عدة دقائق) | يمنع احتراق المحرك بسبب ارتفاع درجة الحرارة |

| ماس كهربائى | ≥13 مرة التصنيف الحالي | لحظية (<10آنسة) | يحمي الدوائر والمحركات من تأثير التيار العالي |

| فشل المرحلة | مرحلة واحدة مفقودة أو اختلال شديد | <1 ثانية | يمنع ارتفاع درجة حرارة الملف الناتج عن التشغيل أحادي الطور |

| انخفاض الجهد | <70% من الجهد المقنن | تأخير (قابل للتعديل) | يتجنب ارتفاع درجة حرارة المحرك أو إعادة التشغيل تحت الجهد المنخفض |

- سيناريوهات التطبيق

التحكم المباشر في البدء لمختلف المحركات غير المتزامنة ثلاثية الطور (الطاقة ≥15 كيلو واط, 415V)

المعدات التي تتطلب عمليات بدء وإيقاف متكررة (على سبيل المثال, مضخات, المشجعين)

الآلات الصناعية تتطلب حماية موثوقة (تجهيز الأغذية, معدات التعبئة والتغليف)

يستبدل المقاول التقليدي + مزيج التتابع الحراري, توفير مساحة مجلس الوزراء

خاتمة

من خلال تكنولوجيا الرحلة المركبة الحرارية والمغناطيسية, يجمع GV2ME20C بمهارة بين الحساسية الحرارية للشريط ثنائي المعدن وخاصية الاستجابة السريعة للملف الكهرومغناطيسي, توفير حماية شاملة وموثوقة للمحركات الكهربائية. هذا “الكل في واحد” التصميم لا يبسط نظام التحكم فحسب، بل يعزز أيضًا سلامة وموثوقية تشغيل المعدات, مما يجعله منتج كلاسيكي في مجال التحكم بالمحركات الصناعية.

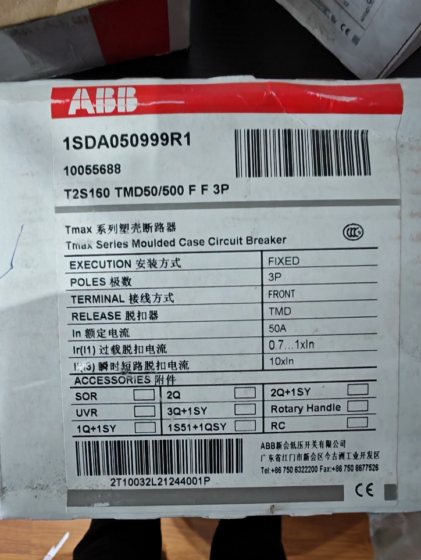

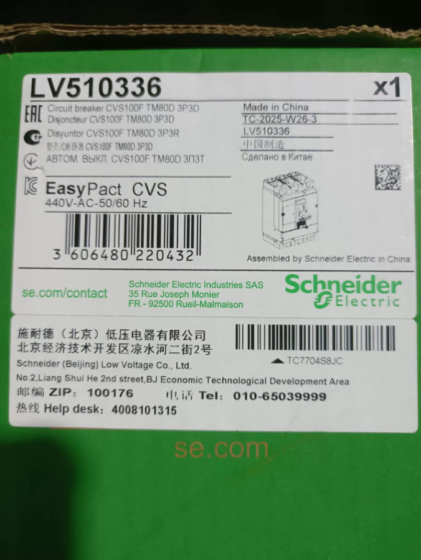

المقاولين,قاطع الدائرة,العاكس للطاقة الشمسية,عداد كهرباء,البطاريات الشمسية

المقاولين,قاطع الدائرة,العاكس للطاقة الشمسية,عداد كهرباء,البطاريات الشمسية

NH42-63-318x560.png)