- 모델 해석

C10F32D100 is the complete order code of Schneider’s new-generation ComPacT NSX series 성형 케이스 회로 차단기. The meaning of each segment is as follows:

| 코드 세그먼트 | 의미 | 설명 |

| C10 | Frame Size and Breaking Capacity | C10 = NSX100F, frame current 100A, breaking capacity Class F (36kA@415VAC) |

| 에프 | Breaking Capacity Class | F = 36kA@415VAC, suitable for standard industrial applications |

| 3 | Number of Poles | 3 = 3-pole (3P3D, three-phase three-wire system) |

| 2D | Trip Unit Type | 2D = MicroLogic 2.2 electronic trip unit with display function |

| 100 | 정격전류 | 100에이, adjustable range 90-100A |

- 핵심 기술 매개변수

기본 매개변수

| 매개변수 | 값 | 설명 |

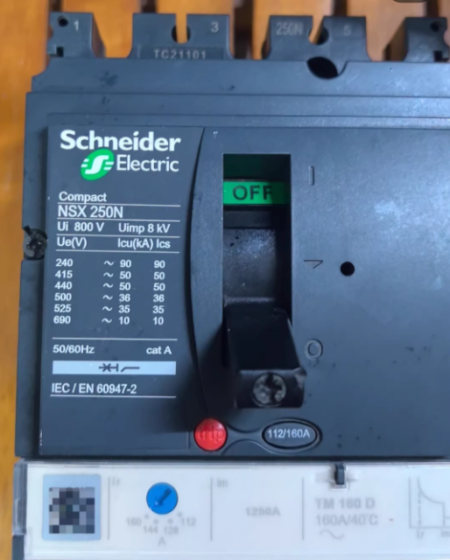

| 제품 유형 | Molded Case Circuit Breaker (MCCB) | New-generation ComPacT NSX100F |

| 정격전압 | 690VAC/50-60Hz | Maximum operating voltage |

| 정격전류 (Iu) | 100에이 | Continuous operating current |

| Ultimate Breaking Capacity (중환자실) | 36kA@415VAC | Ultimate breaking capacity |

| Service Breaking Capacity (Ics) | 36kA@415VAC (100%) | Service breaking capacity |

| Mounting Type | Fixed | Standard mounting, plug-in type optional (C10F32D100P) |

| Protection Category | Category A | Complies with IEC 60947-2 standard |

MicroLogic 2.2 Trip Unit Parameters

| Protection Function | Characteristic | Adjustable Range |

| Long-time Delay Protection (엘) | Overload protection, inverse time-lag | 0.8-1.0脳Iu (90-100에이) |

| Short-time Delay Protection (S) | Short-circuit protection, definite time-lag | 3-6脳Iu, adjustable |

| Instantaneous Protection (나) | Short-circuit instantaneous tripping, fixed | 10脳Iu (1000에이) |

| Display Function | Current measurement and status indication | Real-time display of three-phase current |

Physical and Electrical Characteristics

| 매개변수 | 값 |

| Power Loss | 14.1여 |

| 무게 | Approximately 2.5kg |

| Compliance Standards | IEC 60947-2, GB 14048.2 |

| Certifications | CE, CCC, RoHS |

III. 기능적 특징

- Comprehensive Protection: Provides three-stage protection including long-time delay, short-time delay and instantaneous protection, effectively preventing overload and short-circuit faults.

- Precise Control: Compared with thermal-magnetic trip units (TM series), electronic trip units offer more accurate protection curves and adjustable parameters.

- Status Visualization: MicroLogic 2.2 is equipped with LED display for real-time monitoring of current and fault status.

- 모듈형 디자인: Supports a variety of accessories (보조 접점, alarm contacts, undervoltage release, 등.) for flexible installation.

- Environmental Friendly: Schneider Green Signature design, reducing energy consumption and carbon footprint.

- Easy Operation: Ergonomic handle for labor-saving operation; front-mounted accessories reduce wiring time by 40%.

- 응용 시나리오

- Industrial Power Distribution Systems: Used as main switch or branch switch to protect motors, transformers and distribution lines.

- Building Electrical Systems: Low-voltage distribution cabinets in commercial buildings and industrial plants.

- Motor Control Centers (MCC): Protect three-phase motors from locked rotor and overload conditions.

- Data Centers: Power protection for critical loads to ensure power supply continuity.

- New Energy Sector: DC-side protection of photovoltaic inverters and energy storage systems (additional configuration required).

- Product Comparison

Comparison with Trip Units of the Same Series

| 모델 | Trip Unit Type | Main Differences | 응용 시나리오 |

| C10F32D100 | MicroLogic 2.2 | Electronic trip unit with display, three-stage protection | Industrial applications requiring precise protection and monitoring |

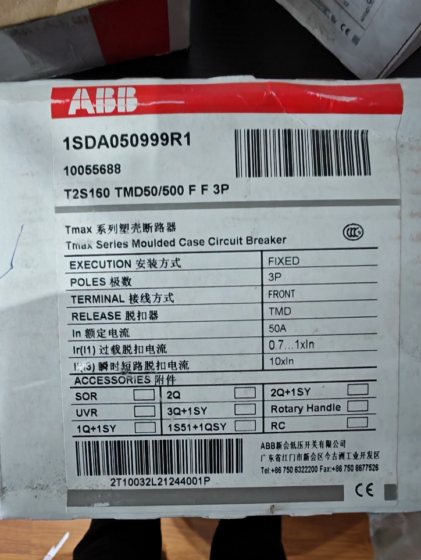

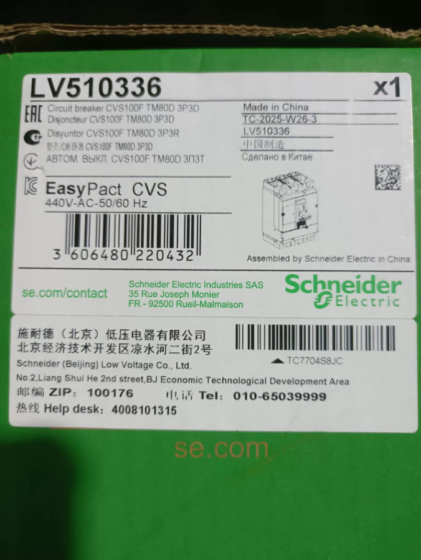

| C10F3TM100 | TM100D Thermal-Magnetic Trip | Thermal-magnetic trip unit, two-stage protection, cost-effective | Simple power distribution without precise adjustment requirements |

| C10F33D100 | MicroLogic 3.2 | Added earth fault protection (30-3000엄마) |

Comparison with Chint Alternative Models

| 슈나이더 모델 | Chint Alternative Model | Similarities | Differences |

| C10F32D100 | NM1-125S/3300 100A | 3-pole, 100에이, 36kA breaking capacity | Chint adopts thermal-magnetic trip unit without display; Schneider adopts electronic trip unit with display |

| NM1-125H/3340 100A | 3-pole, 100에이, electronic trip unit | Chint has 50kA breaking capacity with slightly different protection functions |

- Selection and Usage Recommendations

- Selection Key Points

Select protection curves according to load types: 모터 부하용, it is recommended to set short-time delay to 5-6×Iu

Breaking capacity should be greater than the expected short-circuit current of the system

Consider future expansion; rated current should be slightly higher than the actual load current

- Installation Precautions

Ensure the mounting surface is flat and the tightening torque meets requirements (screw torque 25N·m)

Corresponding cable lugs must be used for terminal connections to avoid heating caused by poor contact

Leave sufficient heat dissipation space around and avoid close installation with heat-generating components

- Maintenance Recommendations

정기점검 (적어도 1년에 한 번): appearance, tightness status, flexibility of operating mechanism

Check contact condition after short-circuit tripping and replace if necessary

Clean with dry compressed air to avoid moisture and dust accumulation

Ⅶ. Troubleshooting Guide

| 결함 현상 | 가능한 원인 | Troubleshooting Steps |

|---|---|---|

| Failure to Close | 1. Undervoltage release without power supply 2. Trip unit malfunction 3. Mechanical lockout | 1. Check control power supply (if equipped) 2. Measure trip unit coil resistance 3. Manually reset the trip mechanism |

| False Tripping | 1. Overload 2. Short circuit 3. Improper trip unit parameter setting | 1. Check load current 2. Check line insulation 3. Reset trip unit parameters |

| No Display After Tripping | 1. Trip unit power supply failure 2. Trip unit damage | 1. Check trip unit power supply 2. Replace the trip unit |

접촉기,회로 차단기,태양광 인버터,전기 계량기,태양 전지

접촉기,회로 차단기,태양광 인버터,전기 계량기,태양 전지

NH42-63-318x560.png)