3‑pole contactor from domestic TeSys Giga series, AC‑3 475A/440V, coil 100–250V AC/DC wide voltage, standard 1NO+1NC auxiliary contacts. Suitable for high‑power motor control and power switching. Supports contact wear diagnosis and can be used with LR9G series thermal relays.

1 기본 매개변수 & Naming Explanation

| 목 | 사양 | Description |

| 모델 | LC1G475KUEC | Domestic TeSys Giga series, 3피(3아니요), AC‑3 ≤440V 475A, 100–250V AC/DC coil |

| Series | TeSys Giga (LC1G) | New generation high‑power contactor from Schneider, replaces old LC1D475 |

| Poles | 3피(3아니요) | 3‑pole normally open, for three‑phase circuit control |

| 정격전류 | 475에이 (AC‑3, ≤440V) | Rated operational current of main circuit |

| Coil voltage | 100–250V AC/DC | Wide‑voltage design, compatible with various control supplies |

| Coil frequency | 50/60헤르츠 | Compatible with global mains frequencies |

| 보조 접점 | 1NO+1NC | 표준 구성, expandable with more aux contacts |

| Applicable standards | IEC 60947‑4‑1, GB/T 14048.4 | Complies with international and national standards |

| Version | China version (suffix C) | Designed for domestic market; no UL certification; global version without C |

2 Key Performance Data

| Utilization category | Rated power (400다섯) | Rated power (440다섯) | Short‑time withstand current |

| AC‑3 (normal motor starting/running) | 대략. 250kW | 대략. 265kW | 10500에이 (1에스) |

| AC‑4 (frequent starting/reversing) | 대략. 180kW | 대략. 190kW | – |

| AC‑1 (resistive load) | 대략. 475kW | 대략. 475kW | – |

3 Applications & 특징

Applications

Direct starting, forward/reverse control, star‑delta starting of high‑power three‑phase asynchronous motors

Industrial power switching and distribution system control

Inductive load control with power factor ≥ 0.95

Heavy‑duty industries: building electrical, 야금, chemical, mining, 등.

Key Features

- High performance: Up to 620A at AC‑3, 1050A at AC‑1 for heavy‑duty applications

- Smart diagnosis: Built‑in contact wear detection for predictive maintenance

- Wide‑voltage coil: 100–250V AC/DC reduces spare parts inventory

- 모듈형 디자인: Supports various accessories (aux contacts, mechanical interlock, surge suppressor, 등.)

- Safe & reliable: Excellent arc extinguishing, suitable for harsh industrial environments

4 Mounting & Wiring Information

Mounting dimensions (China version LC1G475C)

Width: 대략. 140mm

키: 대략. 270mm

깊이: 대략. 150mm

Mounting: Standard 35mm DIN rail or screw mounting

무게: 대략. 10.6kg

Wiring requirements

- Main circuit terminals: Suitable for copper/aluminum cables; crimping lugs recommended

- Control circuit terminals: Suitable for 1.5–2.5mm² control cables

- Clearance: ≥50mm left & right, ≥100mm top & bottom for proper heat dissipation

5 Accessory Compatibility & Matching Products

| Accessory type | Recommended model | 기능 |

| Thermal overload relay | LR9G475 | Matches LC1G475KUEC, provides motor overload protection |

| Mechanical interlock | For LC1G series | For forward/reverse control; prevents simultaneous closing |

| Surge suppressor | For LC1G series | Protects coil against voltage spikes |

| Auxiliary contact module | For LC1G series | Expands NO/NC contacts for complex control |

6 Cross‑Brand Alternatives

| Brand | Replacement model | Match level | Notes |

| 씨줄 | AF460‑30‑11 (100–250V AC/DC) | 높은 | Rated 460A, close to 475A; verify load margin |

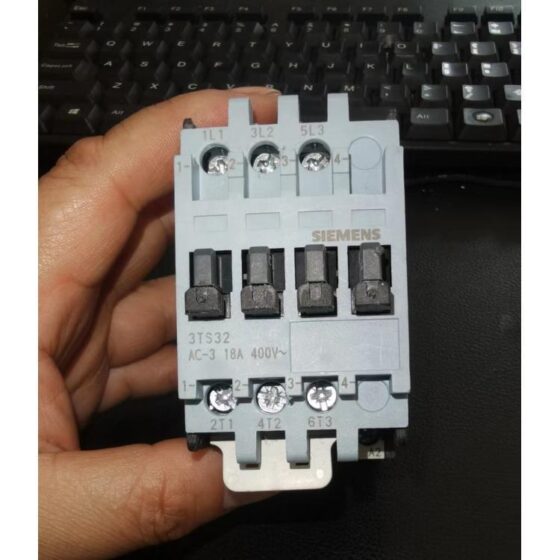

| 지멘스 | 3RT2076‑6AP36 (100–250V AC/DC) | 높은 | Sirius series, 475에이, fully compatible |

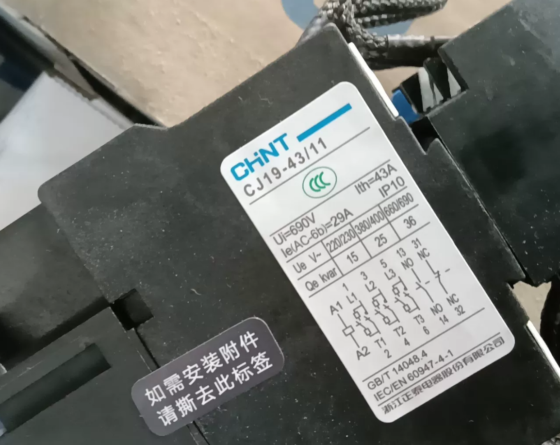

| 친트 | CJX1‑475/22 (100–250V AC/DC) | 중간 | Domestic alternative; slight performance differences, cost‑effective |

| Changshu Switch | CK3‑475 (100–250V AC/DC) | 중간 | Premium domestic brand, high cost‑performance |

7 Installation & Commissioning Tips

- Pre‑installation inspection

Verify model, rated parameters and control supply match

Check for physical damage, 접촉 산화

Ensure flat mounting surface and secure rail

- Installation steps

DIN rail: Align to 35mm rail, press firmly until locked

Screw mounting: Use M6 screws, torque 8–10N·m

배선: Main circuit first, then control circuit; observe terminal torque

- Commissioning & testing

No‑load test: Apply control power; check smooth operation, abnormal noise

Load test: Run under load; monitor current, coil temperature

Aux contact test: Verify NO/NC switching and contact resistance

- Maintenance recommendations

Regularly inspect contact wear; replace if wear >1mm

Clean arc chamber; remove dust and metal particles

Check coil insulation resistance ≥1MΩ

Retighten all terminals to avoid overheating

8 Selection Notes

- Select contactor according to load type (AC‑3/AC‑4/AC‑1)

- For motor control: Contactor rated current ≥ 1.1 × motor rated current

- For frequent starting/reversing (AC‑4): Derate by 20–30%

- For unstable control supply: Prefer wide‑voltage coil models

- When used with thermal relay: Ensure matching ratings

Installation Manual – Schneider Domestic TeSys LC1G475KUEC 3‑Pole Contactor

Doc No.: DOCA0189ZH‑04 (based on official Schneider TeSys Giga installation guide)

Applicable model: LC1G475KUEC (domestic TeSys Giga 3‑pole contactor)

Version: January 2023

⚠️ Safety Warnings (Must Read)

| Hazard type | Preventive measures |

| Electric shock / explosion / arc flash hazard | 1. Disconnect all power (main and control) before installation |

| 2. Only qualified electricians may operate | |

| 3. Use appropriate PPE | |

| 4. Comply with electrical safety codes (예를 들어, NFPA 70E) | |

| 5. Install in non‑hazardous areas (IEC 60079) | |

| Mechanical injury hazard | 1. Contactor approx. 10.6kg; support during installation |

| 2. Avoid finger pinching between contactor and mounting plate/rail | |

| 3. Use proper tools to prevent slipping injury | |

| Overheating hazard | 1. Maintain required clearances: ≥50mm sides, ≥100mm top/bottom |

| 2. Do not store flammables near contactor | |

| 3. Inspect cooling regularly |

1 Product Overview

1.1 Product Identification

모델: LC1G475KUEC

Series: Domestic TeSys Giga (LC1G)

Poles: 3피 (3아니요, 3‑pole normally open)

정격전류: AC‑3 475A (440다섯)

Coil voltage: 100–250V AC/DC (wide voltage)

보조 접점: 1NO+1NC standard

Standards: IEC 60947‑4‑1, GB/T 14048.4

Version: China version (suffix C; no UL certification)

1.2 치수 (Unit: mm)

| Dimension | 값 |

| Width | 140 |

| 키 | 270 |

| 깊이 | 150 |

| Mounting hole spacing | 100×120 (bottom hanging + fixing holes) |

2 Pre‑Installation Preparation

2.1 Tools

Phillips screwdriver (PH3)

Hex key (per fixing screw size)

Torque wrench (5–20N·m range)

Wire stripper (1.5–2.5mm² control & large main cables)

Crimping tool (for cable lugs)

Multimeter (coil resistance & insulation check)

Spirit level

2.2 Materials

Mounting plate (metal, thickness ≥3mm, flat, burr‑free)

M6 mounting screws (min. 4 pcs)

Cable lugs (for main circuit cables)

Control cable (1.5–2.5mm² copper)

Main cable (≥150mm² copper recommended)

Insulation tape / heat‑shrink tubing

Marker pen

2.3 환경 요구 사항

| 매개변수 | Requirement |

| Temperature | -5°C ~ +40°C (operating); -25°C ~ +55°C (storage) |

| 습기 | ≤95% (non‑condensing) |

| 고도 | 2000m 이하 (derate above) |

| Pollution degree | 2 (industrial environment) |

| Vibration | ≤5.9m/s² (5–150Hz) |

| Inclination | ≤30° from vertical |

2.4 Product Inspection

- Check packaging and transport damage

- Verify model label (LC1G475KUEC)

- Inspect contacts for oxidation, pitting, foreign matter

- Manually actuate armature; check smooth operation

- Measure coil resistance with multimeter

- Test auxiliary contact switching

3 Installation Procedure (Surface Mounting)

메모: Domestic LC1G475KUEC supports surface mounting only; not for DIN rail.

3.1 Mounting Plate Drilling (선택 과목)

- Mark holes at 100×120mm

- Drill diameter: φ6.5mm (for M6)

- Deburr after drilling

3.2 Hanging & Fixing

- Hang: Locate bottom hanging holes onto mounting plate pins/screws

- Preliminary fix: Hand‑tighten top M6 screws

- Final fix: Torque all 4 screws to 3±0.3N·m (top‑down, diagonal)

- Level check: Ensure inclination ≤30°

3.3 Accessory Installation (Aux Contacts / Mechanical Interlock)

- 보조 접점

Disconnect control power

Align and push into top slot until click

Verify secure locking

- Mechanical interlock

Keep ≥50mm between two contactors

Mount interlock on sides

Adjust to prevent simultaneous closing

Test manually

4 Wiring Procedure

4.1 Pre‑Wiring Notes

- Confirm all power disconnected

- Main cables must use proper crimp lugs

- Control cable strip length: ~8–10mm

- Sequence: Main circuit first, then control

4.2 Main Circuit Wiring (3피, L1/L2/L3 → T1/T2/T3)

- Open main terminal cover

- Insert lugged cables

- Torque:

Copper: 12±1N·m

Aluminum: 14±1N·m (with anti‑oxidant)

- Securely tighten; check by gentle pull

- Close terminal cover

4.3 Control Circuit Wiring (Coil A1/A2, Aux NO/NC)

- Open control terminal cover

- 코일:

A1: Control supply +/Line

A2: Control supply –/Neutral

- Aux contacts:

아니요: 13–14 (holding, indication)

NC: 21–22 (interlock, fault)

- Control terminal torque: 2±0.2N·m

- Close cover

4.4 Wiring Diagram

5 Mounting with Thermal Relay (LR9G475)

5.1 Direct Installation

- Confirm matching: LC1G475KUEC + LR9G475

- Align thermal relay to top slot

- Push down until click

- Check secure mounting

- Connect pre‑installed busbars

- Torque busbar screws: 8±0.8N·m

5.2 Wiring Notes

- Main: Power → Contactor → Thermal relay → Motor

- Control: Thermal relay NC (95–96) in series with contactor coil

- Set thermal relay current to motor rated current

6 Commissioning & Testing

6.1 No‑Load Test

- Apply control power (main open)

- Check smooth closing, no abnormal noise

- Verify aux contact switching

- Check rapid opening

- Repeat 3–5 times

6.2 Load Test

- Apply main power

- Start motor; check current within rating

- Monitor coil temperature ≤60°C after 1h

- Check terminal temperature ≤70°C (infrared)

- Simulate overload; verify relay trip

6.3 Contact Wear Diagnosis (LC1G Feature)

- Monitor via auxiliary contacts

- Warning when wear >1mm

- Replace contactor promptly

7 Maintenance & Service

7.1 Routine Inspection (every 6 months)

- De‑energize; inspect for dirt, damage

- Clean arc chamber (compressed air ≤0.3MPa)

- Check contact resistance ≤500μΩ

- Check coil insulation ≥1MΩ (500V megger)

- Retighten terminals

- Test operation

7.2 Replacement Schedule

| Part | Interval | Replacement standard |

| 주요 연락처 | 1–2 years | Wear >1mm or resistance >500μΩ |

| Aux contacts | 2–3 years | Poor switching |

| 코일 | 3–5 years | Insulation aging, weak closing |

| Arc chamber | 5 연령 | Degraded performance |

7.3 문제 해결

| Symptom | Possible causes | 해결책 |

| Contactor fails to close | 1. No control power | 1. Check wiring |

| 2. Coil fault | 2. Replace coil | |

| 3. Mechanical jam | 3. Clean & lubricate | |

| Loud noise on closing | 1. Dirty iron core | 1. Clean surfaces |

| 2. Broken ring | 2. Replace ring | |

| 3. Low coil voltage | 3. Check supply | |

| Contacts overheating | 1. Loose terminals | 1. Retighten |

| 2. Oxidized contacts | 2. Clean/replace contacts | |

| 3. Overload | 3. Check load | |

| Slow opening | 1. Fatigued spring | 1. Replace spring |

| 2. Mechanical jam | 2. Clean mechanism | |

| 3. Residual magnetism | 3. Check coil |

8 안전 & Environment

8.1 Safe Disposal

- Disconnect all power before scrapping

- Remove all wiring

- Separate metal & plastic for recycling

- Contacts contain silver alloy; recycle as precious metal

8.2 Environmental Compliance

RoHS compliant; free of Pb, Hg, 등.

Plastic housing recyclable

Dispose per local regulations

9 Appendix – Technical Data

| 매개변수 | 값 |

| Rated operational current (AC‑3, 400다섯) | 475에이 |

| Rated power (400다섯, AC‑3) | 250kW |

| Short‑time withstand current (1에스) | 10500에이 |

| Coil voltage | 100–250V AC/DC |

| Coil power | Inrush: ~200VA, Sealed: ~20W |

| Aux contact rated current | 5에이 (AC‑15, 220다섯) |

| Mechanical life | 10,000,000 운영 |

| Electrical life (AC‑3) | 1,000,000 운영 |

접촉기,회로 차단기,태양광 인버터,전기 계량기,태양 전지

접촉기,회로 차단기,태양광 인버터,전기 계량기,태양 전지

NH42-63-318x560.png)