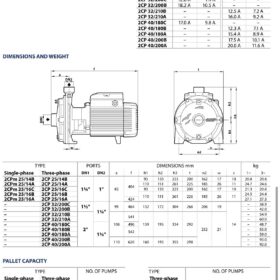

- Interpretarea modelului

| Model Component | Sens |

| 2CP | Double-impeller centrifugal pump series (2 indicates double impellers, CP indicates centrifugal type) |

| 25 | Pump body nominal diameter specification (DN25), inlet and outlet diameters are 11″ respectively (ISO 228/1 thread) |

| 16 | Performance grade identifier, used to distinguish models with different performance curves in the same series |

| O | Power grade identifier, representing the highest power version (2.2kW/3HP) among products of the same specification |

| 2CPm | Single-phase version (2CP is three-phase version) |

- Parametrii tehnici de bază (50Hz, Three-phase 380/400V)

| Parameter Category | Valoare | Remarks |

| Motor Power | 2.2kW (3HP) | IE3 high-efficiency motor, Class F insulation, IPX4 protection class |

| Curent nominal | 5.3O (400V-s)/9.2O (230V-t) | Rated operating current |

| Rotational Speed | 2900rpm | Standard asynchronous motor speed |

| Flow Range | 0-160l/min (0-9.6m/h) | Under HS=0m working condition |

| Head Range | 32-68m | Head variation corresponding to flow rate of 0-160l/min |

| Maximum Suction Lift | 7m | Upper limit of vacuum water suction height |

| Maximum Working Pressure | 10bar | System pressure resistance capacity |

| Medium Temperature | -10C~+90C | Applicable liquid temperature range |

| Temperatura ambiantă | -10C~+40C | Working ambient temperature limit |

| Continuous Operation | S1 Duty | Capable of 24-hour uninterrupted operation |

| Greutate | 27.3kg | Weight of three-phase version |

III. Structural Features and Material Description

- Structural Composition

Double-impeller Design: Delivers higher head and more stable performance curve, improving efficiency by 10-15%.

Integral Cast Iron Pump Body: High-rigidity structure with vibration and noise reduction, suitable for high-pressure working conditions.

Integrated Mechanical Seal: Combination of graphite/ceramic/NBR materials, ensuring long-term leak-free operation.

Stainless Steel Motor Shaft: Made of AISI 431 material, featuring corrosion resistance and high strength to extend service life.

- Core Component Materials

| Numele componentei | Material | Characteristics |

| Pump Body/Inlet & Outlet | Cast Iron | High strength, high pressure resistance, ISO 228/1 standard threaded interface |

| Impeller | Brass | Wear and corrosion resistance, high-efficiency hydraulic design, suitable for clean water applications |

| Mechanical Seal | Graphite/Ceramic/NBR | Low friction coefficient, high temperature resistance, excellent leak-proof performance |

| Motor Shaft | Stainless Steel AISI 431 | Corrosion resistance, high strength, fatigue resistance |

| Motor Winding | Copper | IE3 efficiency class, Class F insulation, suitable for frequency converter drive |

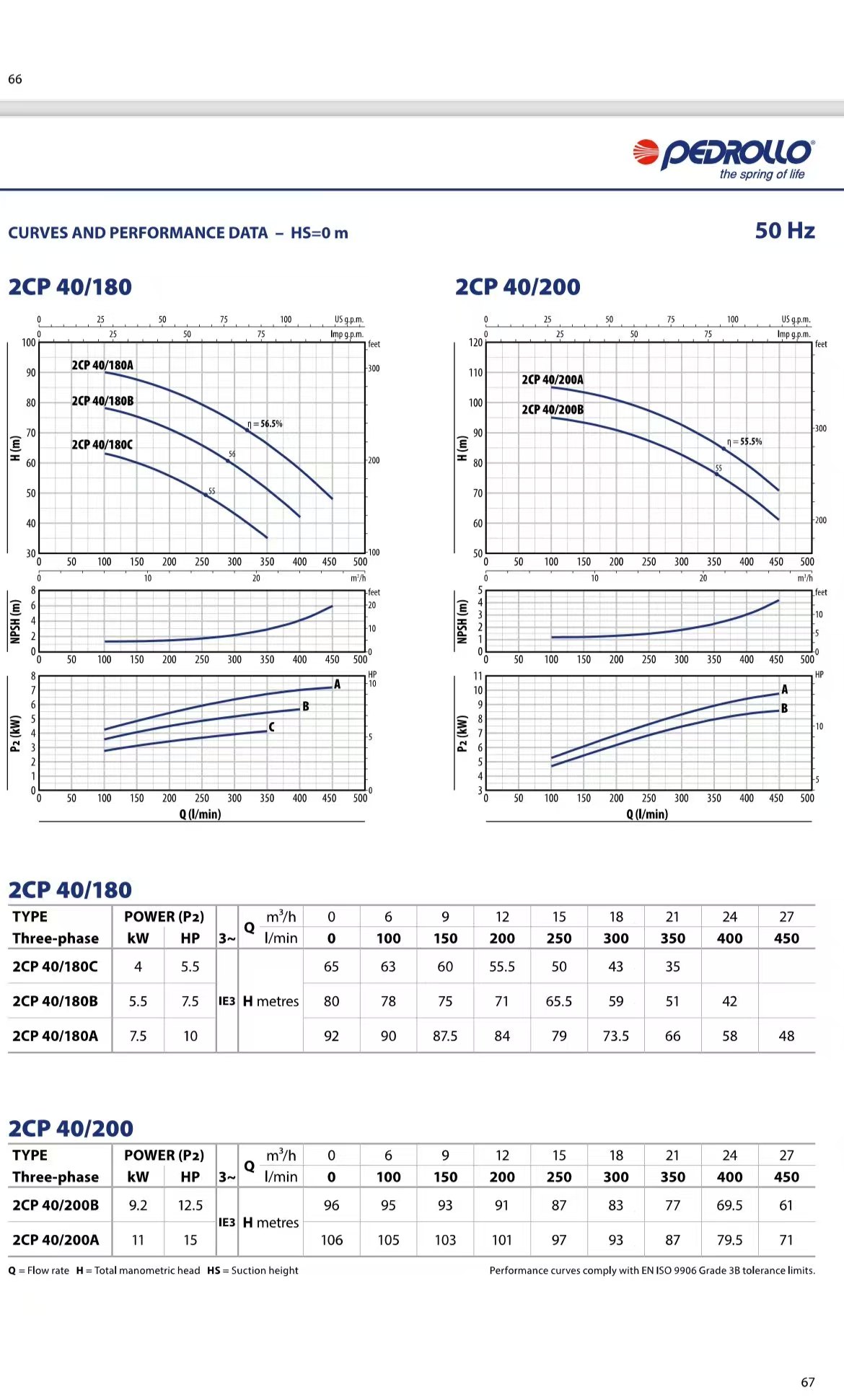

- Key Points of Performance Curve (HS=0m)

| Flow Rate (l/min) | 0 | 20 | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Head (m) | 68 | 67 | 65 | 62 | 58.5 | 54 | 48 | 40.5 | 32 |

| Eficienţă (%) | – | 45 | 52 | 58 | 62 | 63 | 60 | 55 | 48 |

The performance curve complies with the tolerance standard of EN ISO 9906 Grade 3B.

- Scenarii de aplicare

- Residential Booster System: Water pressure boosting for high-rise residential buildings and villas, with optimal performance when used with a pressure tank.

- Commercial Building Water Supply: Pressure stabilization for centralized water supply systems in hotels, office buildings, hospitals, etc.

- Industrial Auxiliary System: Cooling water circulation, cleaning systems, low-pressure fire protection pressure stabilization systems.

- Agricultural Irrigation: Pressure source for drip irrigation/spray irrigation systems in small and medium-sized farms and greenhouses.

- Municipal Facilities: Pressure boosting for small water plants and secondary water supply systems.

- Installation and Operation Key Points

- Specificații de instalare

Install in a well-ventilated and dry place, avoiding rain and direct sunlight.

The foundation shall be flat and firm, with shock-absorbing pads used to reduce vibration transmission.

Valves and pressure gauges should be installed at the inlet and outlet for easy maintenance and monitoring.

The suction pipeline must be well-sealed to avoid air leakage affecting suction lift.

It is recommended to install a check valve to prevent water hammer.

- Operation Restrictions

No-idling operation is prohibited (which will damage the mechanical seal).

Ensure that the pump chamber and suction pipeline are filled with water before starting.

The medium must be clean water or liquid with chemical properties similar to clean water.

During continuous operation, ensure that the inlet pressure is ≥0.1bar to prevent cavitation.

VII. Fault Diagnosis and Troubleshooting

| g | ||

| Fenomen de eroare | Cauze posibile | Troubleshooting Methods |

| Pump Fails to Start | Power supply failure; motor protection device tripped; wiring error | Check power supply; reset thermal relay; verify wiring diagram |

| Insufficient Flow | Excessive suction lift; impeller blockage; inlet and outlet valves not fully opened | Lower installation height; clean the impeller; check valve opening degree |

| Low Head | Low voltage; abnormal rotational speed; impeller wear | Check power supply voltage; confirm motor speed; replace the impeller |

| Excessive Noise | Unstable foundation; cavitation; bearing wear | Reinforce the foundation; reduce suction lift/increase inlet pressure; replace bearings |

| Leakage | Damaged mechanical seal; aging O-ring; loose connection | Replace mechanical seal; replace O-ring; tighten connecting bolts |

| Motor Overheating | Overload operation; poor heat dissipation; unbalanced voltage | Adjust working condition to rated range; improve ventilation; check power supply |

VIII. Selection Suggestions

- Working Condition Matching Principle

When selecting flow rate, consider 1.1-1.2 times the maximum water demand of the system.

When selecting head, consider total system resistance loss + required working pressure + safety margin (0.5-1bar).

Ensure that the actual operating point falls within the high-efficiency zone of the performance curve (efficiency>55%).

- Recommended Supporting Equipment

Pressure tank: Recommended volume ≥10L, used to stabilize pressure and reduce start-stop frequency.

Pressure switch: Adjustable range of 0.8-4bar, matching system pressure requirements.

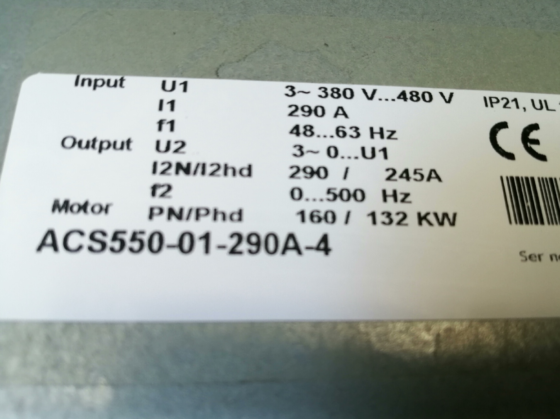

Frequency converter: Used for precise control of flow/pressure, saving energy by 30-50% (suitable for variable load working conditions).

Protection devices: Thermal relay, întrerupător de circuit (Tip D), surge protector.

- Alternative Model Reference

For higher head requirements: 2CP 32/210A (7.5kW, maximum head 112m).

For larger flow requirements: 2CP 40/200A (11kW, flow rate 9.6m³/h).

For single-phase power supply applications: 2CPm 25/16A (2.2kW, single-phase 230V).

- Ciclul de întreținere

| Maintenance Item | Cycle | Content |

| Inspecție zilnică | Daily | Operating status; pressure; noise; scurgere |

| Filter Cleaning | Weekly | Clean the suction port filter to prevent blockage |

| Fastening Connection | Monthly | Check all connection parts to prevent loosening |

| Bearing Lubrication | 6 Months | Supplement lubricating grease according to the instruction manual (if applicable) |

| Mechanical Seal Inspection | 1 Year | Check seal condition and replace if necessary |

| Comprehensive Maintenance | 2 Years | Disassemble and inspect; replace wearing parts; test performance |

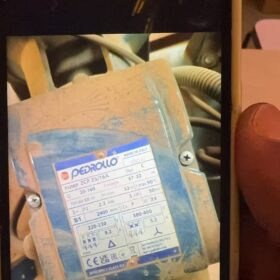

The Pedrollo 2CP 25/16A is a high-efficiency and reliable double-impeller centrifugal pump specially designed for medium and high-pressure clean water delivery, suitable for various civil and industrial application scenarios. Its IE3 high-efficiency motor, high-quality materials and precision manufacturing process ensure long-term stable operation. With proper installation and maintenance, it can provide excellent performance and economic benefits. During selection, the working condition requirements should be strictly matched, and professional technical personnel should be consulted for the optimal solution when necessary.

Structural Features of Pedrollo 2CP 25/16A Double-impeller Centrifugal Pump

- Core Structural Design Features

- Back-to-back Double-impeller Design (Core Technical Highlight)

Back-to-back Series Double Impellers: Two brass impellers are arranged symmetrically along the axial direction to form a “back-to-back” structure, which effectively balances radial load and extends bearing service life.

Segmented Pump Body: The cast iron pump body is divided into suction section and discharge section, facilitating maintenance and impeller replacement. It has high overall rigidity and pressure resistance up to 10bar.

High-efficiency Hydraulic Channel: Optimized flow channel design reduces hydraulic loss, improves efficiency by 10-15%, and the high-efficiency zone covers a wider flow range (40-120l/min, efficiency>55%).

Axial Force Balance: The double-impeller design counteracts axial thrust, reducing the load on mechanical seals and bearings, and improving operational stability.

- Close-coupled Structure

The motor is rigidly connected to the pump body without a coupling, reducing transmission loss and improving overall efficiency.

Shortens axial dimension, featuring compact structure and small floor area, with a weight of only 27.3kg (three-phase version).

Reduces vibration and noise transmission, enabling quieter operation with vibration level ≤2.5mm/s (ISO 10816 standard).

- Key Component Materials and Characteristics

| Numele componentei | Material | Technical Characteristics | Advantage Description |

| Pump Body (Suction/Discharge Section) | Cast Iron (Electrophoretic Coating Treatment) | Tensile strength ≥250MPa, uniform wall thickness, ISO 228/1 threaded interface | High strength, corrosion resistance, good sealing performance, compatible with standard pipe fittings |

| Impeller | Brass (CuZn40Pb2) | Precision casting, dynamic balance accuracy Grade G6.3 | Wear and corrosion resistance, high hydraulic efficiency, suitable for clean water and slightly sandy liquid |

| Motor Shaft | Stainless Steel AISI 431 (ÎN 10088-3 1.4104) | Diameter 18mm, surface hardening treatment, roughness Ra≤0.8μm | High strength, corrosion resistance, fatigue resistance, extending seal service life |

| Pump Cover | Stainless Steel AISI 304 | Corrosion resistance, flatness ≤0.05mm | Prevent liquid leakage, protect internal components, suitable for food-grade applications |

| Mechanical Seal | Graphite/Ceramic/NBR Combination | Dynamic ring: ceramic; static ring: graphite; elastomer: NBR; working pressure ≤10bar | Low friction coefficient (μ≤0.1), high temperature resistance (≤90°C), leak-free operation ≥8000 hours |

| Bearing | Deep Groove Ball Bearing 6203 ZZ | Double-sided dust cover, pre-lubricated, limit rotational speed ≥10000rpm | Low noise, long service life, suitable for continuous operation (S1 duty) |

| O-ring/Sealing Gasket | NBR Rubber | Shore hardness 70±5, temperature resistance range -20°C~+100°C | Good elasticity and sealing performance, anti-aging, compatible with various water qualities |

III. Motor System Structural Features

- High-efficiency Motor Design

IE3 Energy Efficiency Class (three-phase version): Saves about 10% more energy than IE2 motors, complying with EU ErP Directive requirements.

Class F Insulation: Heat-resistant temperature of 155°C, improving motor overload capacity and service life.

IPX4 Protection Class: Splash-proof design, suitable for outdoor installation (needs shelter), with good dust-proof performance.

TEFC Cooling Method: Totally enclosed fan-cooled, high heat dissipation efficiency, suitable for continuous operation.

Built-in Thermal Protection: Three-phase version is equipped with PTC thermistor, single-phase version is equipped with thermal relay to prevent motor burnout due to overheating.

- Electrical Connection and Control

The junction box is located on the top of the motor with IP55 protection class, facilitating wiring and maintenance.

Compatible with Frequency Converter Control: The motor is designed to support 0-50Hz stepless speed regulation, realizing precise control of flow and pressure, and saving energy by 30-50%.

Rated current 5.3A (400V three-phase), starting current ≤7 times the rated current, suitable for direct starting or star-delta starting.

- Sealing and Protection System Features

- Mechanical Seal Technology

Integrated Single-face Mechanical Seal: Installed between the pump cover and motor shaft without requiring additional cooling system.

Static Ring Fixed Structure: Realizes automatic compensation through stainless steel spring and O-ring, adapting to slight axial movement and vibration of the shaft.

Anti-dry Running Protection Design: Moderate contact pressure on the sealing surface reduces wear during dry running (long-term dry running is still prohibited).

- Overall Protection Design

Electrophoretic Coating on Pump Body Surface: Corrosion resistance, UV resistance, extending outdoor service life.

Double Sealing of Motor Junction Box: Prevent moisture and dust from entering, protecting electrical components.

Shock-absorbing Foot Design: Four cast iron feet with rubber shock-absorbing pads reduce vibration transmission to the foundation structure.

- Installation and Maintenance Convenience Design

- Compatibilitate cu instalare

Inlet and outlet diameters 1¼”×1″ (DN25×DN25), standard ISO 228/1 thread, can be directly connected to PPR, PVC or metal pipelines.

Flexible Installation Direction: Can be installed horizontally or vertically (motor on top) to adapt to different space requirements.

Pressure gauge interfaces are reserved at both inlet and outlet for convenient system pressure monitoring and fault diagnosis.

- Maintenance Convenience

Design modular: The pump cover is fixed by 4 bolts. After disassembly, the impeller and mechanical seal can be directly replaced without disassembling the entire pump body.

Bearing Pre-lubrication Design: Long-acting lubricating grease is filled before leaving the factory, no need for supplementation within 2 ani.

Standardized Wearing Parts: Mechanical seals, O-rings and other accessories have strong versatility, making procurement and replacement convenient.

- Structural Advantage Summary

Structural Advantage Practical Application Value Back-to-back Double-impeller Design Balances radial load, reduces bearing wear, extends service life by more than 30% IE3 High-efficiency Motor Significant energy saving during long-term operation, reducing operating costs Integral Cast Iron Pump Body High pressure resistance, vibration and noise reduction, suitable for high-pressure working conditions Stainless Steel Shaft + Graphite/Ceramic Seal Corrosion resistance, leak-free, long maintenance cycle Close-coupled Structure High transmission efficiency, low vibration, small installation space requirement Modular Maintenance Design Reduces downtime and maintenance costs

The structural design of Pedrollo 2CP 25/16A fully embodies the precision craftsmanship and reliability concept of Italian manufacturing. The double-impeller design gives it obvious advantages in the field of medium and high-pressure clean water delivery, and it is widely used in residential pressure boosting, commercial building water supply, industrial circulation systems and other scenarios. Its structural features not only ensure efficient and stable operating performance, but also reduce the whole-life cycle cost, making it a cost-effective double-impeller centrifugal pump product.

Contactor,întrerupător de circuit,invertor solar,contor electric,baterii solare

Contactor,întrerupător de circuit,invertor solar,contor electric,baterii solare

NH42-63-318x560.png)