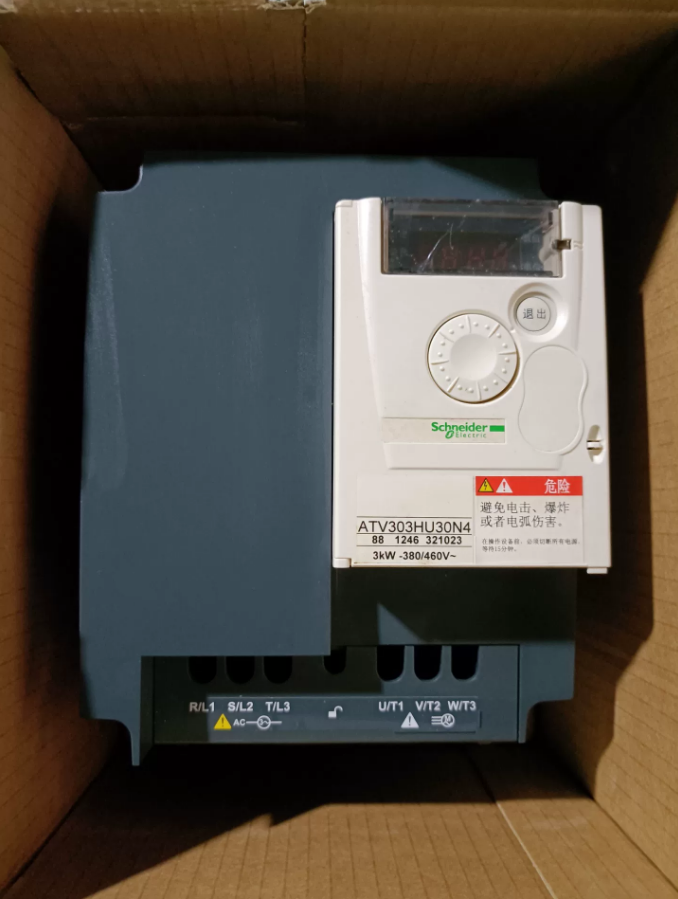

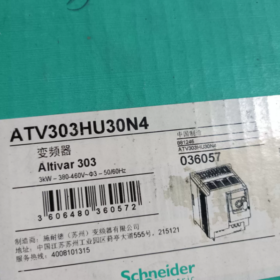

Schneider ATV303HU30N4 is a general-purpose frequency converter launched by Schneider Electric.

Parámetros básicos: Suitable for 380~460V three-phase AC power supply system, with a rated adapted motor power of 30kW and a rated output current of approximately 60A. The power supply frequency ranges from 50Hz to 60Hz, with an allowable frequency fluctuation range of -5% a +5%.

Diseño Estructural: Compact structure with high-efficiency heat dissipation performance, supporting side-by-side installation without derating operation, which can save electric control cabinet space. The operating ambient temperature range is -10℃ to +50℃; with enhanced ventilation, it can operate stably at a maximum temperature of +60℃. The internal key circuit boards are treated with three-proof paint. The shell protection grade is IP20, and some areas meet the IP41 standard.

Control Performance: Supports optimized V/F control, sensorless vector control (SVC), and quadratic torque control optimized for fan/pump loads. It has excellent overload capacity, capable of continuous operation at 150% rated current for 60 artículos de segunda clase, and the instantaneous starting torque can reach more than 170%. It is equipped with a built-in DC braking unit, which can provide braking capacity of about 70% rated torque in the standard configuration; when an external braking resistor is connected, the braking performance can be increased to 150%.

Communication Function: Standard equipped with RS485 interface, supporting Modbus RTU communication protocol, and integrating CANopen master station function. It can also access mainstream industrial networks by selecting Profibus DP, DeviceNet or EtherNet/IP communication cards.

Operation Interface: Equipped with a high-contrast Chinese graphic display terminal which is detachable, with clear menu logic and supporting the “Easy Start” wizard function. Parameter configuration can be completed through the panel, PowerSuite software or easy downloader, supporting parameter backup, cloning and batch deployment.

Input and Output Interfaces: Provides 6-channel programmable digital inputs (DE), 2-channel analog inputs (AI, supporting 0–10V / 0–20mA), 1-channel relay output and 1-channel analog output (HACIA), meeting the requirements of complex control logic.

Función de protección: Equipped with a complete protection mechanism, covering multiple real-time monitoring and automatic response functions such as overcurrent, sobretensión, subtensión, calentamiento excesivo, motor phase loss, short circuit and ground fault.

Campos de aplicación: Widely used in large-flow fans, high-pressure water pumps, air compressors, material conveying lines, large-scale packaging machinery, mining equipment and various industrial scenarios requiring stable speed regulation and high-efficiency energy-saving control.

Schneider ATV303HU30N4 is a 30kW, 380-460V three-phase general-purpose frequency converter. With its characteristics such as high overload capacity (150% rated current for 60 artículos de segunda clase), wide-temperature operation (-10℃ to +50℃), built-in braking unit (70% rated torque) and Modbus communication, it is widely used in multiple industrial fields, especially suitable for high-power load control requiring stable speed regulation and high-efficiency energy saving.

- Fluid Conveyance Field (Fans/Water Pumps/Air Compressors)

As a 30kW high-power frequency converter, ATV303HU30N4 performs excellently in fluid conveyance systems:

Large-flow Fans: Used for factory ventilation, boiler induced draft, sewage treatment aeration, etc.. Realize precise air volume control through speed regulation, with energy saving up to 30-50%.

High-pressure/Large-flow Water Pumps: Suitable for high-rise building water supply, industrial circulating water systems, mining drainage, etc., supporting constant pressure water supply control logic.

Large-scale Air Compressors: Control the speed of air compressors, automatically adjust output according to air pressure, reduce unloading energy consumption and extend equipment service life.

Vacuum Pumps: Realize precise vacuum degree control in chemical and pharmaceutical industries, improving process stability.

- Material Handling and Conveying Systems

Suitable for heavy-load, long-distance material conveying scenarios:

Large-scale Material Conveying Lines: Mining belt conveyors, port loading and unloading equipment, warehousing automated sorting systems, realizing stable start-stop and multi-machine synchronous control.

Hoisting Equipment: Small cranes, lifting platforms, material hoists, providing starting torque of more than 170% to ensure heavy-load starting safety.

Sorting and Packaging Lines: Cintas transportadoras, distributors and stackers in automated production lines, improving production efficiency and precision.

III. Textile and Printing & Dyeing Industry

Targeting the continuous operation and precise speed regulation requirements of textile machinery:

| Equipment Type | Application Description |

| Large-scale Looms | Circular knitting machines, water-jet/air-jet looms, controlling spindle speed to ensure uniform fabric density |

| Printing and Dyeing Equipment | Singeing, desizing, scouring and bleaching combined machines, setting machines, realizing multi-unit synchronous speed regulation to ensure dyeing uniformity |

| Cotton Textile Equipment | Winding machines, drawing machines, combers, precisely controlling yarn tension and winding speed |

| Dehydrators/Dyeing Vats | Controlling speed to achieve efficient dehydration and uniform dyeing, improving product quality |

- Ceramics and Building Materials Industry

Adapting to the characteristics of high dust and large temperature fluctuations in ceramic production environments:

Kiln Control Systems: Controlling kiln fans, combustion-supporting fans and cooling water pumps, realizing precise temperature curve control and improving product qualification rate.

Forming and Processing Equipment: Large-scale distributing machines, polishing machines, edge grinding machines, ensuring uniform material distribution and surface processing precision.

Printing and Glazing Equipment: Ceramic tile printing machines, automatic glazing lines, realizing precise synchronization of speed and position to improve pattern consistency.

- Woodworking and Furniture Manufacturing

Meeting the high-speed, high-precision cutting and processing requirements of woodworking machinery:

Large-scale Sanding Machines/Coating Machines: Controlling sanding belt speed and feeding speed to ensure plate surface flatness and coating uniformity.

Edge Banding Machines/Cutting Machines: Precisely controlling tool speed, improving processing precision and reducing material waste.

Multi-axis Woodworking Lathes: Realizing multi-axis synchronous control to process furniture parts with complex shapes.

Polishing Machines/Grinding Machines: Adapting to different wood hardness through speed regulation, improving surface treatment quality.

- Machine Tool and Metal Processing

Suitable for high-power spindle and feed system control:

CNC Lathes/Milling Machines: Controlling spindle speed to achieve constant linear speed cutting and improve machining surface quality.

Grinding Machines/Electric Spindles: Providing stable low-speed operation and fast response to ensure grinding precision.

Wire Drawing Machines/Winding Machines: Controlling metal wire drawing speed and tension to achieve uniform winding and reduce wire breakage rate.

Stamping and Bending Equipment: Controlling hydraulic pump speed, automatically adjusting power output according to load, saving energy while improving production efficiency.

VII. Packaging and Printing Machinery

Targeting the multi-process synchronization and high-precision positioning requirements of the packaging and printing industry:

Large-scale Packaging Machinery: Bag making machines, cartoning machines, sealing machines, controlling the synchronization of conveying, formación, sealing and other links.

High-speed Printing Machines: Newspaper printing machines, commercial web offset printing machines, realizing precise synchronization of paper feeding, printing and paper collecting to improve overprinting precision.

Film Laminating Machines/Die-cutting Machines: Controlling material conveying speed to ensure film laminating flatness and die-cutting precision.

Label Printing Machines: Realizing multi-color printing synchronization, improving label quality and production efficiency.

VIII. Mining and Construction Machinery

Adapting to harsh industrial environments (dust, vibration, temperature fluctuations):

Mining Equipment: Small crushers, screening machines, feeders, providing reliable speed regulation control and extending equipment service life.

Construction Machinery: Mixing stations, concrete delivery pumps, controlling mixing speed and delivery pressure to improve construction quality.

Tunnel Ventilation/Drainage: Used for large-scale fans and drainage pumps in tunnel engineering to ensure construction safety.

- Otras aplicaciones industriales

Refrigeration and Air Conditioning Systems: Controlling large-scale water chillers and cooling tower fans, realizing precise temperature control with significant energy saving effect.

Pharmaceutical and Chemical Industry: Mixers, reactors, centrifuges, meeting the requirements of precise control of process temperature and speed.

Paper Making Industry: Paper machine wire sections, press sections, drying sections, realizing multi-unit synchronous speed regulation to improve paper quality.

Application and Selection Advantages

- High-power Adaptability: 30kW rated power, suitable for large loads without the need for multi-machine parallel connection.

- Adaptabilidad ambiental: IP20 protection + three-proof paint treatment, adapting to dusty and humid industrial environments.

- Rich Built-in Functions: Quadratic torque control (suitable for fans and water pumps), SVC sensorless vector control (suitable for heavy loads), built-in braking unit (reducing external component costs).

- Convenient Communication: Standard equipped with RS485/Modbus, supporting industrial network integration, facilitating remote monitoring and centralized control.

With its characteristics of strong versatility, high reliability and easy maintenance, ATV303HU30N4 has become an ideal choice for 30kW-level industrial speed regulation applications, widely serving manufacturing, municipal engineering, mining and other fields.

contactor,cortacircuitos,inversor solar,medidor electrico,baterias solares

contactor,cortacircuitos,inversor solar,medidor electrico,baterias solares

NH42-63-318x560.png)