The CHINT NXM250S-3300/180A disjoncteur à boîtier moulé (MCCB) is a protective device specially designed for low-voltage power distribution systems, suitable for industrial, commercial, and residential applications. The following is a detailed analysis of its technical parameters, application scenarios, selection points, and maintenance suggestions:

- Paramètres techniques de baseDisjoncteur Chint NB2LE C20

- Performances électriques

Courant nominal: 180UN, suitable for medium to high-load circuits (par ex., moteurs, lighting distribution boxes).

Capacité de coupure:

Class S: ICU (ultimate breaking capacity) = 50kA, Ics (service breaking capacity) = 36kA (72% of Icu), applicable to scenarios where the short-circuit current ≤ 50kA.

Short-time withstand current (Icw): 30le (1 deuxième), ensuring stable contact closure during faults.

Numéro de pôle: 3P. (three-phase), supporting grounding systems such as TN-C-S.

Type de voyage: Thermomagnetic (the second “3” in 3300 represents thermomagnetic tripping), providing overload long-time delay (inverse time) and short-circuit instantaneous protection.

Tension nominale: C.A. 400 V (up to 690V supported, but the 250A frame is not applicable at 690V).

- Caractéristiques mécaniques

Méthode d'installation: Type fixe, front-wiring design, compatible with standard 35mm rails.

Operation Mode: Manual closing, supporting remote shunt tripping (accessories need to be selected separately).

Dimensions: Approximately 105mm (W) × 188mm (H) × 85mm (D), compact size to save distribution cabinet space.

- Adaptabilité environnementale

Température de fonctionnement: -5°C à +70°C, adaptable to high-temperature environments (par ex., unairconditioned power distribution rooms).

Altitude: ≤2000m, degré de pollution 3, suitable for industrial environments.

- Scénarios d'application

- Applications typiques

Power Distribution System: As a branch circuit switch to protect lines from overload and short-circuit faults (par ex., floor distribution boxes in commercial complexes).

Contrôle du moteur: Provides direct starting protection for motors below 150kW (needs to be used with contactors).

Renewable Energy: Protection for the output side of photovoltaic inverters, supporting bidirectional current (reverse power feeding capability needs to be confirmed).

- Industry Adaptation

Industrie: Power distribution for factory production lines, pump houses, and other power equipment.

Construction: Control of lighting and air conditioning systems in intelligent buildings.

Infrastructure: Small data centers, hospital emergency power systems.

III. Technical Features and Advantages

- Intelligent Protection Functions

Overload Long-time Delay: Inverse time characteristics, allowing adjustment of the tripping curve according to load characteristics (par ex., motors require extended tripping time).

Short-circuit Instantaneous Protection: Quickly breaks short-circuit current with a response time <10MS.

Protection contre les sous-tensions: Shunt undervoltage release can be selected (needs to be ordered separately), automatically tripping when the voltage is below 70% de la valeur nominale.

- High-reliability Design

Arc-guided Contacts: Reduces arc energy and extends contact life to 10,000 electrical operations.

Vibration-resistant Structure: Passed IEC 60068-2-6 vibration testing, suitable for industrial scenarios with frequent start-stop operations.

Flame-retardant Housing: Made of PA66+GF30 material, heat-resistant up to 125°C, compliant with UL94 V-0 normes.

- Flexible Expandability

Abundant Accessories: Supports auxiliary contacts (AX/AL-M1), alarm contacts (AX/AL-M3), shunt trip coils, etc., enabling remote monitoring and fault alarm.

Phase Spacers: Arc-shaped arc-dividing plates can be selected to enhance interphase insulation and reduce short-circuit arc risks.

- Selection and Installation Suggestions

- Points de sélection

Capacité de coupure adaptée: Choose Class S (50le) or Class H (70le) based on the system short-circuit current. Par exemple, Class S is usually sufficient when the transformer capacity ≤1600kVA.

Trip Unit Type:

Thermomagnetic (3300): Suitable for mixed loads (par ex., motors and lighting combined).

Electromagnetic (3200): Short-circuit protection only, suitable for pure resistive loads.

Accessory Selection:

– Remote control: Shunt trip coil (MX) + contact auxiliaire (HACHE).

– Leakage protection: Need to select the NXMLE series (par ex., NXMLE-250S/3300-180A).

- Installation Notes

Spécifications de câblage: Use 240mm² copper cables (need to crimp OT terminals), tighten with a torque of 8N·m to avoid excessive contact resistance.

Conditions environnementales: The installation location should be well-ventilated to prevent dust accumulation (par ex., regular cleaning is required in textile factories).

Exigences de mise à la terre: The metal housing must be reliably grounded with a yellow-green two-color wire, and the grounding resistance ≤4Ω.

- Maintenance et gestion des pannes

- Entretien courant

Cleaning and Inspection: Use dry compressed air to remove internal dust quarterly, and check contact wear (replace if wear exceeds 1mm).

Test de fonctionnement: Use a testing box annually to verify tripping characteristics, ensuring that overload protection does not trip within 2 heures à 1.13 times the rated current and trips within 1 heure à 1.45 fois.

- Défauts courants et solutions

Inability to Close: Check if the energy storage spring is loose or if the trip unit is in the “re-tripping” position (needs manual reset).

False Tripping: View fault records through the control unit. If it is an instantaneous overcurrent, adjust the short-circuit protection threshold (par ex., increase from 10In to 12In).

Contact Overheating: Check if wiring terminals are loose or if the load has long-term exceeded the rated current (needs to be derated).

- Warranty Policy

– The product comes with a 24-month warranty, and non-human damage can be replaced for free. It is recommended to purchase through CHINT authorized dealers to ensure after-sales service.

- Certification et conformité

Certification nationale: Passed CCC certification (numéro de certificat 2020980307002101), compliant with GB14048.2 standards.

International Standards: Compliant with IEC 60947-2, but CE certification is not explicitly marked; separate confirmation is required for exports.

VII. Comparison and Alternative Solutions

- Comparison with Other NXM Series Models

NXM250H/3300: Breaking capacity increased to 70kA, suitable for systems with higher short-circuit currents (par ex., parallel transformers).

NXM250S/3300 vs NM1-250S: The NXM series is a new-generation product with a smaller size and higher breaking capacity (NM1-250S has a breaking capacity of 50kA but a larger size).

- Competitor References

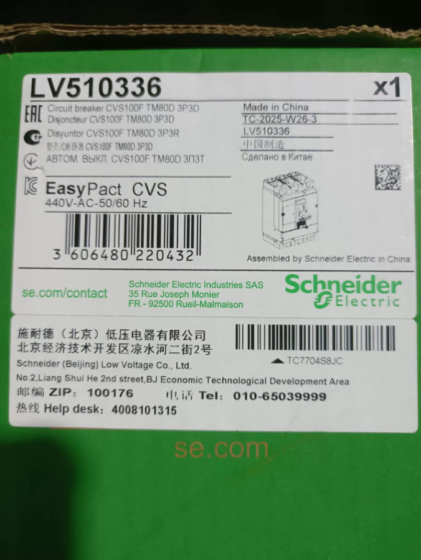

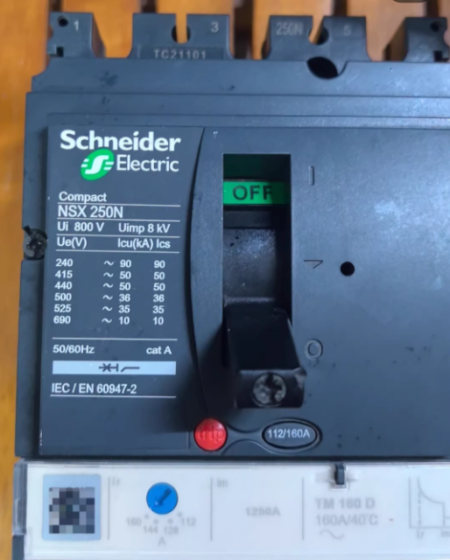

Schneider EasyPact NSX250N: Breaking capacity 50kA, supporting electronic trip units, but 30% higher in price.

Delixi CDB6LE-250: 15% lower in price, but breaking capacity is only 40kA, suitable for cost-sensitive civil projects.

VIII. Procurement and Technical Support

Channels: Purchase through CHINT’s official website or contact WhatsApp: 0086-13811255435, and verify the product serial number and CCC mark.

Résumé: CHINT NXM250S-3300/180A has become an ideal choice for medium and low-voltage power distribution with its high cost-effectiveness, reliable protection performance, and flexible expandability. When selecting, focus on matching the breaking capacity and accessory requirements, and conduct regular maintenance after installation to ensure long-term stable operation.

Comparison Between CHINT NXM250S-3300/180A and Schneider MT16N1

The CHINT NXM250S-3300/180A molded case circuit breaker (MCCB) and Schneider MT16N1 air circuit breaker (PBR) differ significantly in technical positioning, functional design, and application scenarios. The following is a comparative analysis of core dimensions:

- Product Positioning and Basic Types

NXM250S: Belongs to MCCB, positioned as a mid-range power distribution protection device, suitable for overload and short-circuit protection of branch circuits, with a rated current covering 180A (250Un cadre).

MT16N1: Belongs to ACB, positioned as a high-end power distribution core device, mainly used for main inlets or large-capacity circuits, with a rated current up to 1600A, supporting bidirectional current and complex system protection.

- Comparison of Core Technical Parameters

| Paramètre | NXM250S-3300/180A | MT16N1 |

| Courant nominal | 180UN (250Un cadre) | 1600UN |

| Capacité de coupure | Icu = 50 kA, Ics=36kA (72% of Icu) | Icu = 50 kA, Ics=50kA (100% of Icu) |

| Short-time Current | Icw=30kA (1s) | Icw=50kA (1s) |

| Control Unit | Thermomagnetic tripping (basic overload + protection contre les courts-circuits) | MIC series intelligent control unit (four-stage protection + communication) |

| Durée de vie mécanique | 10,000 electrical operations | 20,000 mechanical operations |

| Installation Mode | Type fixe, front wiring | Fixed/drawer type, supporting rear wiring/mixed connection |

III. Differences in Functions and Expandability

- Depth of Protection Functions

NXM250S: Only provides two-stage thermomagnetic protection (overload long-time delay + short-circuit instantaneous), without selective protection capability, unable to distinguish fault levels.

MT16N1: Achieves four-stage protection (overload long-time delay, short-circuit short-time delay, instantaneous, ground fault) through the MIC control unit, supporting flexible adjustment of protection parameters to realize selective protection and narrow the power outage range.

- Intelligence and Communication Capability

NXM250S: No built-in communication function, requiring a shunt trip coil to achieve remote opening, but cannot access energy management systems (EMS).

MT16N1: Supports communication-type control units such as MIC 6.0D, integrating Modbus, Profibus protocols, enabling real-time monitoring of power quality, fault recording, and seamless docking with smart grids.

- Accessory Ecosystem

NXM250S: Accessories focus on basic control (shunt trip coils, contacts auxiliaires), lacking advanced expansion functions.

MT16N1: Provides rich accessories, including phase spacers, door interlocks, electric operating mechanisms, module de communication, etc., supporting reverse power feeding and distributed energy access.

- Application Scenarios and Adaptability

NXM250S:

Scénarios typiques: Commercial building floor distribution boxes, small industrial motor control (≤150kW), residential power distribution systems.

Limitations: Requires manual reset after tripping, no selective protection, unsuitable for scenarios with high requirements for power supply continuity.

MT16N1:

Scénarios typiques: Data center main inlets, hospital emergency power systems, factory power distribution main switches, photovoltaic inverter outlet protection.

Avantages: Drawer-type structure supports quick replacement, and the intelligent control unit can achieve precise fault positioning, ensuring continuous power supply for critical loads.

- Reliability and Environmental Adaptability

- Conception structurelle

NXM250S: Molded case packaging, taille compacte (100×40×3mm, 1kilos), but internal contacts and arc extinguishers are small, with higher temperature rise under long-term high loads.

MT16N1: Metal frame + conception modulaire, contact cross-sectional area more than 5 times that of NXM250S, better heat dissipation performance, suitable for long-term full-load operation.

- Environmental Tolerance

NXM250S: Adaptable to -5°C to +70°C, altitude ≤2000m, but weak vibration resistance, unsuitable for industrial environments with frequent start-stop operations.

MT16N1: Passed IEC 60068-2-6 vibration testing, wider operating temperature range (-5°C à +70°C), anti-condensation design applicable to high-humidity environments (par ex., underground power distribution rooms).

- Certification et conformité

NXM250S: Passed domestic CCC certification, and some models (such as the NXMLE series) comply with CE and CB standards, but international market adaptability is limited.

MT16N1: Complies with international standards such as IEC 60947-2, UL, and ship classification societies, supports global project deployment, and has passed ISO 50001 energy efficiency certification, suitable for green energy projects.

VII. Cost and Maintenance

Procurement Cost: The price of NXM250S is about 1/3 à 1/2 of MT16N1, suitable for budget-sensitive projects.

Maintenance Cost:

NXM250S: Maintenance-free design, but overall replacement is required after contact wear, with lower single maintenance costs.

MT16N1: Modular design supports component replacement (such as control units, contact groups), but maintenance complexity is higher, requiring professional technicians.

Résumé: How to Choose?

Scenarios Prioritizing NXM250S:

Limited budget, simple protection requirements (par ex., residential, small commercial), need for quick installation, and no intelligent monitoring requirements.

Scenarios Prioritizing MT16N1:

Main inlets or large-capacity circuits, requiring selective protection and intelligent communication (par ex., data centers, hospitals), long-term high-load operation, or harsh industrial environments.

The essential difference between the two lies in functional positioning: NXM250S is an economical and practical “branch guardian,” while MT16N1 is a “power distribution hub” ensuring system stability. Users should make comprehensive decisions based on system scale, protection complexity, and long-term operation and maintenance costs.

Contacteur,disjoncteur,onduleur solaire,compteur électrique,batteries solaires

Contacteur,disjoncteur,onduleur solaire,compteur électrique,batteries solaires

NH42-63-318x560.png)