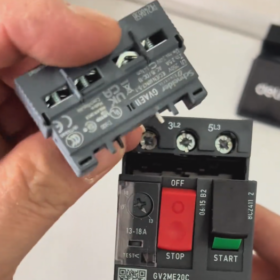

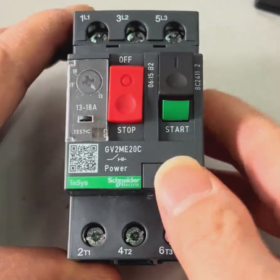

シュナイダーモータースターター GV2ME20C

Schneider Motor Starter GV2ME20C is a product under the TeSys Deca GV2 series, primarily designed for the protection and control of three-phase electric motors. Below is its detailed introduction:

Basic Parameters

定格電流: 18あ, with a thermal overload protection setting range of 13-18A

極数: 3P

Voltage Type: AC, 50/60Hz

定格電圧: Rated operational voltage and insulation voltage of 690V AC; rated impulse withstand voltage of 6kV

Magnetic Trip Current: 223あ

寸法: 89mm × 44.5mm × 78.2mm

重さ: 0.26kg

Product Features

保護機能: Equipped with a thermal-magnetic trip unit, it provides overload and short-circuit protection for motors, along with phase failure protection capability.

取付方法: Supports DIN rail mounting, allowing vertical or horizontal installation for convenience and space-saving.

Operation Method: Controlled via push-button operation for manual starting and stopping of motors.

Comprehensive Certifications: Complies with relevant standards such as EN/IEC 60947, and holds certifications including 3C, CE, UL, and CSA, ensuring excellent safety and reliability.

Mechanical Service Life: Boasts a mechanical service life of 100,000 cycles, meeting long-term operational requirements.

応用分野

Suitable for industries such as food/agricultural products, packaging/papermaking/printing, and steel/metal processing, delivering reliable protection and control for electric motors.

Working Principle of Schneider Motor Starter GV2ME20C

- Product Positioning and Basic Structure

The GV2ME20C is a manual motor starter and protector in Schneider’s TeSys Deca series, integrating control and protection functions. It is suitable for the start-stop control and multiple electrical protection of three-phase asynchronous motors.

Core Structure:

3-pole thermal-magnetic circuit breaker (3P) with a rated current of 18A and a thermal protection setting range of 13-18A

Push-button operation panel (Start/Stop)

Built-in thermal-magnetic trip unit (bimetallic strip + electromagnetic coil)

Auxiliary contacts and trip indication device

DIN rail mounting base

- Overview of Working Principle

Dual Protection Mechanism: The thermal-magnetic trip unit combines two protection characteristics to achieve comprehensive motor protection:

Thermal Protection (過負荷保護): Utilizes the bimetallic strip to sense temperature rise caused by overcurrent, implementing inverse-time delayed tripping.

Magnetic Protection (短絡保護): Employs the electromagnetic coil to detect large short-circuit currents, enabling instantaneous tripping.

Ⅲ. Detailed Working Mechanism

- Normal Operation State

Power is connected to the three-phase terminals (L1/L2/L3) and transmitted to the motor (T1/T2/T3) via the main contacts.

Press the Start button; the mechanical latch keeps the main contacts closed, and the motor starts running.

When the current stays within the rated range, neither the thermal element nor the electromagnetic coil is activated.

- Working Principle of Overload Protection (Thermal Protection)

Core Component: Bimetallic strip (composed of two metals with different thermal expansion coefficients bonded together)

| Stage | Working Process |

| Abnormal Current Rise | Motor overload → current exceeds the setting range → temperature of the thermal element increases |

| Deformation Accumulation | The bimetallic strip bends and deforms due to temperature differences |

| Trip Triggering | Deformation reaches the threshold → pushes the trip mechanism → releases the latch → main contacts open |

| Protection Characteristic | Inverse-time characteristic: The more severe the overload, the shorter the tripping time (matching the motor’s thermal characteristics) |

Setting Method: Adjust the initial position of the bimetallic strip via the front-panel knob to set the protection current value (13-18あ).

- Working Principle of Short-Circuit Protection (Magnetic Protection)

Core Component: Electromagnetic trip coil + armature mechanism

In the event of a short circuit → current surges sharply (≥13 times the rated current, approximately 223A) → the coil generates a strong magnetic field.

Magnetic field attraction overcomes spring resistance → the armature pulls in rapidly → strikes the trip lever.

The latch is released → the main contacts open instantaneously (response time < 10MS) → the short-circuit current is cut off.

- Principle of Phase Failure Protection

Monitors the balance of three-phase currents. When any phase is missing or severely unbalanced:

The three-phase current difference exceeds the set threshold → the thermal element activates (due to increased current in non-fault phases) → triggers tripping.

Protection response time < 1 second, preventing motor burnout caused by single-phase operation.

- Other Protection Functions

Undervoltage Protection: When the power supply voltage drops below approximately 70% of the rated value, the undervoltage trip unit activates to cut off the power supply.

Shunt Trip: Can be connected to an external control signal (例えば, PLC) to realize remote emergency shutdown.

Mechanical Interlock: Features a “power-off to open the door” function to ensure maintenance safety; the operation buttons can be locked to prevent misoperation.

- Operation and Control Methods

- Manual Control

Start: Press the Start button → the mechanical latch locks the contacts → the motor is energized and runs.

Stop: Press the Stop button → releases the latch → contacts open → the motor is de-energized.

Fault Reset: Manual reset (press the Reset button) is required after tripping before restarting.

- Remote Control (via External Components)

Used in conjunction with contactors to achieve remote start-stop control via PLC or control systems.

The shunt trip function can receive external signals for emergency shutdown.

- Summary of Protection Characteristics

| Protection Type | Trigger Condition | Response Characteristic | 保護機能 |

| Overload | 1.05~1.5 times the rated current | Inverse-time (several seconds to several minutes) | Prevents motor burnout due to overheating |

| Short-Circuit | ≥13 times the rated current | Instantaneous (<10MS) | Protects circuits and motors from high-current impact |

| Phase Failure | One phase missing or severe imbalance | <1 second | Prevents winding overheating caused by single-phase operation |

| 不足電圧 | <70% of the rated voltage | Delayed (adjustable) | Avoids motor overheating or restarting under low voltage |

- アプリケーションシナリオ

Direct start control of various three-phase asynchronous motors (power ≤15kW, 415V)

Equipment requiring frequent start-stop operations (例えば, pumps, ファン)

Industrial machinery demanding reliable protection (food processing, packaging equipment)

Replaces the traditional contactor + thermal relay combination, saving cabinet space

Conclusion

Through thermal-magnetic composite trip technology, the GV2ME20C skillfully combines the thermal sensitivity of the bimetallic strip and the rapid response characteristic of the electromagnetic coil, providing comprehensive and reliable protection for electric motors. これ “all-in-one” design not only simplifies the control system but also enhances the safety and reliability of equipment operation, making it a classic product in the field of industrial motor control.

コンタクタ,サーキットブレーカー,ソーラーインバーター,電気メーター,太陽電池

コンタクタ,サーキットブレーカー,ソーラーインバーター,電気メーター,太陽電池

NH42-63-318x560.png)