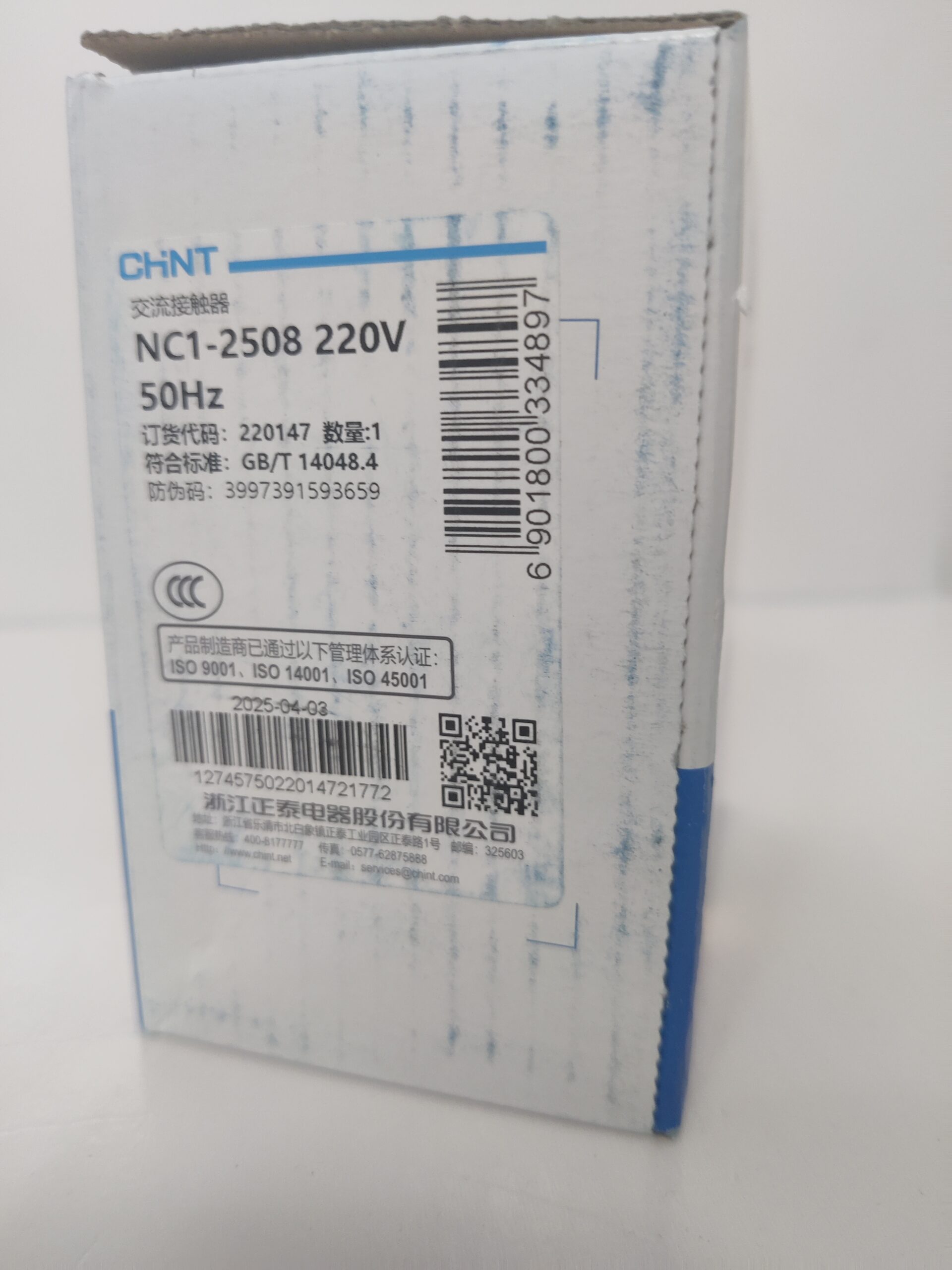

- Model Interpretation

| Model Segment | Description |

| NC1 | Product series code; CHINT Electric NC1 series AC contactor, suitable for remote on/off control of AC circuits and frequent control of AC motors |

| 25 | Rated operating current class; rated operating current is 25A under AC-3 utilization category (at 400V) |

| 8 | Auxiliary contact configuration, 0 normally open + 8 normally closed (actually a 4-pole contactor with 2NO+2NC main contacts; auxiliary contacts need to be configured separately) |

| 220V | Rated control voltage of the coil; AC 220V, compatible with 50/60Hz frequency |

- Core Technical Parameters

| Parameter Category | Specific Index |

| Rated Operating Voltage (Ue) | Three-phase AC 690V (50/60Hz); Rated Insulation Voltage Ui = 800V |

| Rated Operating Current (In) | 25A at 400V under AC-3; 40A at 400V under AC-1; 16A at 690V under AC-3 |

| Utilization Category | AC-1 (non-inductive or slightly inductive loads), AC-3 (starting/running/breaking of squirrel-cage induction motors), AC-4 (frequent starting/reversing/braking of squirrel-cage induction motors) |

| Main Contact Configuration | 4-pole, 2NO+2NC (2 Normally Open + 2 Normally Closed) |

| Auxiliary Contacts | Need separate configuration (e.g., AX series auxiliary contact sets); can be expanded to combinations like 2NO+2NC |

| Coil Parameters | Rated voltage AC 220V, 50/60Hz; Pick-up power approx. 370VA; Holding power approx. 45VA |

| Mechanical Life | ≥10 million cycles (no-load operation) |

| Electrical Life | ≥100,000 cycles under AC-3 (breaking at rated current) |

| Protection Class | IP20 (prevents finger access) |

| Mounting Method | Standard 35mm DIN rail mounting or screw fixing |

| Compliance Standards | IEC/EN 60947-4-1, GB14048.4 |

III. Functional Features

- Flexible Multi-Pole Configuration: 4-pole design (2NO+2NC main contacts) adapts to various circuit control requirements, especially suitable for scenarios requiring bidirectional control or switching of the main circuit.

- Wide Voltage Compatibility: The coil supports universal 50/60Hz frequency, adapts to power grid frequencies in different regions, and ensures stable and reliable control voltage.

- Long Mechanical and Electrical Life: Mechanical life up to 10 million cycles and electrical life of 100,000 cycles under AC-3, meeting the requirements of industrial scenarios with frequent start-stop operations.

- Modular Expansion: Accessories such as auxiliary contact sets and mechanical interlock modules can be added to realize function expansion including signal feedback and reversible control.

- Safe and Reliable Design: Adopts silver alloy contacts with strong anti-welding capability; the high-efficiency arc extinguishing system ensures short arcing distance during breaking, guaranteeing electrical safety.

- High Versatility: Designed with reference to the Schneider LC1 series; can be matched with CHINT NR2 series thermal overload relays to form electromagnetic starters for overload protection.

- Application Scope

- Motor Control: Can control motors up to 11kW (400V three-phase induction motor) under AC-3 category, suitable for frequent start-stop of equipment such as fans, water pumps and conveyors.

- Power Distribution System: Used for remote on/off control of circuits below AC 690V, such as control of non-inductive or slightly inductive loads (AC-1 category) like lighting systems and heating equipment.

- Industrial Automation: Serves as the core component of control circuits such as star-delta starters and reversible contactors, adapting to various motor control schemes including DOL (Direct-On-Line) starting and star-delta starting.

- Building Electrical Engineering: Control circuits of equipment such as fans, air conditioners and water pumps in shopping malls, office buildings, factory workshops and other places.

- Not Suitable For: DC circuits, occasions with frequent reversing and large load inertia (AC-4 dedicated contactors are required), and heavy-duty circuits exceeding rated current.

- Selection Suggestions

- Load Matching:

Motor Load: Select according to motor power; 25A contactor is suitable for ≤11kW three-phase motors at 400V.

Power Distribution Load: Can carry 40A current under AC-1 category, suitable for lighting or heating loads with total power ≤17kW.

- Control Voltage Confirmation: Ensure that the coil voltage (220V) matches the power supply of the control circuit to avoid coil burnout.

- Auxiliary Contact Expansion:

For signal feedback: Install AX-02 auxiliary contact set (2NO).

For interlock control: Install mechanical interlock module (suitable for reversible control).

For alarm function: Install alarm contact module.

- Protection Configuration: Use with NR2-25 series thermal overload relays with setting current 16-25A to achieve motor overload protection.

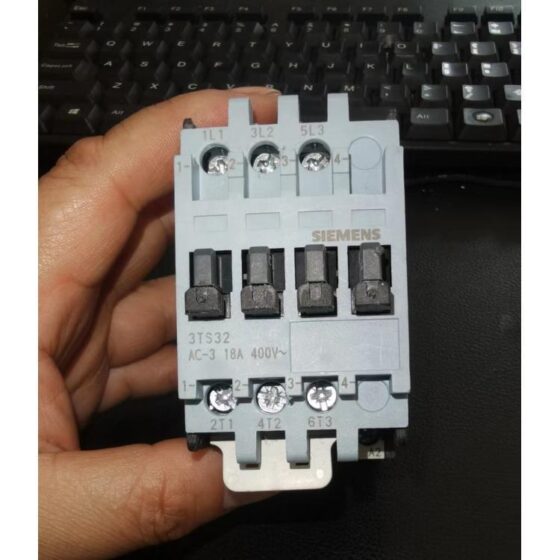

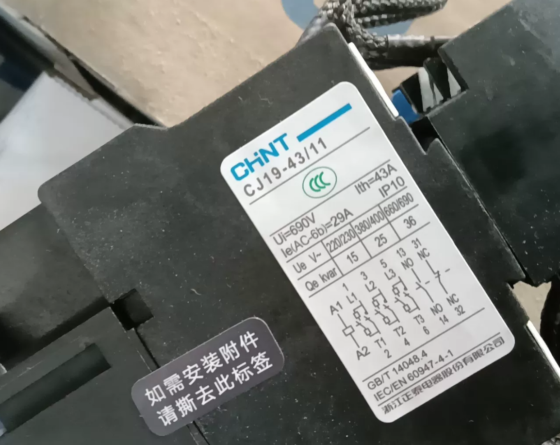

- Brand Replacement Reference:

| Brand | Replacement Model | Core Differences |

| Schneider | LC1D25008M7 220V | Higher price, same auxiliary contact configuration, slightly higher breaking capacity |

| Siemens | 3RT6026-1AN20 220V | Modular design, compatible with Siemens automation systems, higher price |

| Delixi | CJX2-2508 220V | Domestic product of the same grade, consistent parameters, high cost performance |

- Troubleshooting

| Common Faults | Possible Causes | Solutions |

| Coil not pulling in after power-on | 1. Mismatched coil voltage or open circuit in control loop | 1. Verify coil voltage and check control loop wiring |

| 2. Burned coil | 2. Measure coil resistance (approx. several hundred ohms under normal condition); replace if burned | |

| 3. Jammed mechanical mechanism | 3. Clean the interior of the contactor and check for jamming of springs and armature | |

| Loud noise after pull-in | 1. Oil stain or rust on armature end face | 1. Clean armature end face to remove oil stain and rust |

| 2. Broken shading ring | 2. Replace shading ring or contactor body | |

| 3. Low coil voltage | 3. Check control power supply voltage to ensure it is within 卤10% of the rated value | |

| Overheating or welding of contacts | 1. Load current exceeding rated value | 1. Replace with contactor of larger capacity or reduce load |

| 2. Poor contact of contacts | 2. Clean contacts and polish oxide layer; replace contacts if severely damaged | |

| 3. Failure of arc extinguishing system | 3. Check for damage to arc extinguishing cover and replace in time | |

| Abnormal signal of auxiliary contacts | 1. Poor contact of auxiliary contacts | 1. Clean auxiliary contacts and check wiring |

| 2. Loose installation of auxiliary contact set | 2. Reinstall auxiliary contact set and tighten screws | |

| 3. Severe wear of contacts | 3. Replace auxiliary contact set | |

| Frequent coil burnout | 1. Excessive fluctuation of control voltage | 1. Install voltage stabilizer or surge protector |

| 2. Long-term coil energization (exceeding design life) | 2. Optimize control loop to avoid long-term coil energization | |

| 3. High ambient temperature | 3. Improve ventilation and heat dissipation conditions to reduce ambient temperature |

VII. Installation and Maintenance Notes

- Before installation, check that the contactor has no damage to appearance, no oxidation of coil and contacts, and the mechanical mechanism is flexible without jamming.

- When installing on DIN rail, reserve ≥50mm heat dissipation space and avoid close installation with other heating elements.

- During wiring, use wires suitable for 25A current for main circuit terminals (4mm² copper core cable is recommended) and tighten terminal screws (tightening torque 2.5N·m).

- Use 1.5mm² copper core cable for control loop wiring to avoid excessive voltage drop due to insufficient wire diameter.

- Conduct regular inspection every 3 months:

Check contact wear; replace when contact thickness is less than 1mm.

Monitor coil temperature; normal operating temperature should be ≤80℃.

Check flexibility of mechanical mechanism and remove dust and oil stains.

- After a fault occurs, cut off power supply first, troubleshoot and repair before putting into use; operation with fault is strictly prohibited.

Parameter Comparison Table of CHINT NC1 Series Contactors (9A/12A/25A/40A/65A/95A)

| Comparison Dimension | NC1-09 | NC1-12 | NC1-25 | NC1-40 | NC1-65 | NC1-95 |

| Rated Operating Current (AC-3, 400V) | 9A | 12A | 25A | 40A | 65A | 95A |

| Suitable Three-Phase Motor Power (400V) | 4kW | 5.5kW | 11kW | 18.5kW | 30kW | 45kW |

| Rated Operating Current (AC-1, 400V) | 12A | 18A | 40A | 63A | 100A | 150A |

| Rated Insulation Voltage (Ui) | 800V | 800V | 800V | 800V | 800V | 800V |

| Rated Operating Voltage (Ue) | AC 690V | AC 690V | AC 690V | AC 690V | AC 690V | AC 690V |

| Main Contact Configuration | 3NO (3 Normally Open) | 3NO | 2NO+2NC (4-pole) | 3NO | 3NO | 3NO |

| Coil Voltage Options | AC 24/36/110/220/380V | Same as left | Same as left | Same as left | Same as left | Same as left |

| DC 24/110V | ||||||

| Coil Pick-up Power | Approx. 70VA | Approx. 85VA | Approx. 370VA | Approx. 500VA | Approx. 650VA | Approx. 800VA |

| Coil Holding Power | Approx. 8VA | Approx. 10VA | Approx. 45VA | Approx. 60VA | Approx. 80VA | Approx. 100VA |

| Mechanical Life | ≥10 million cycles | ≥10 million cycles | ≥10 million cycles | ≥10 million cycles | ≥10 million cycles | ≥8 million cycles |

| Electrical Life (AC-3) | ≥100,000 cycles | ≥100,000 cycles | ≥100,000 cycles | ≥100,000 cycles | ≥100,000 cycles | ≥80,000 cycles |

| Protection Class | IP20 | IP20 | IP20 | IP20 | IP20 | IP20 |

| Mounting Method | 35mm DIN rail/screw fixing | Same as left | Same as left | Same as left | Same as left | Same as left |

| Matching Thermal Overload Relay | NR2-11.5 | NR2-11.5 | NR2-25 | NR2-40 | NR2-65 | NR2-95 |

| Typical Application Scenarios | Small fans, pumps, lighting control | Conveyors, small compressors | Central air conditioning fans, water pumps | Large fans, air compressors | Injection molding machines, crushers | Cooling towers, large motors |

Supplementary Selection Tips

- Load Matching Priority: For motor loads, select according to rated current under AC-3; for power distribution/lighting loads, select according to rated current under AC-1. The load current shall be ≤80% of the contactor’s rated current to avoid overload.

- Coil Voltage Selection: Prioritize voltage consistent with the control loop (e.g., 220V). DC coils are suitable for industrial scenarios with strong electromagnetic interference to avoid false pull-in.

- Auxiliary Contact Expansion: All specifications can be equipped with AX series auxiliary contact sets (2NO/2NC/1NO+1NC) to meet the needs of signal feedback and interlock control.

- Reversible Control Configuration: Select 2 contactors of the same specification and install mechanical interlock module to prevent main circuit short circuit.

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

NH42-63-318x560.png)