Suitable for overload and phase failure protection of industrial motors; a classic supporting component for motor control.

- Basic Application & Standards

Application: AC 50/60Hz, rated voltage up to 690V, for continuous/intermittent three-phase asynchronous motors, providing overload + differential phase failure protection.

Not suitable for standalone short-circuit protection; must be used with fuses/circuit breakers.

Complies with GB/T 14048.4/5 and IEC 60947-4-1.

Can form a QC36 electromagnetic starter with CJT1 contactors.

Ambient conditions: -5℃ ~ +40℃ (24h average ≤ 35℃), altitude ≤ 2000m, inclination ≤ 5°, no explosive or highly corrosive media.

- Key Technical Parameters

- Frame current: 20A

Setting current available in multiple ranges (0.25–0.35A, 3.2–5A, 10–16A, 14–22A, etc., selected as required).

Trip class: Class 10A

- Auxiliary contacts: 1 NO + 1 NC

AC-15 380V: 0.47A; DC-15 220V: 0.15A

- Wiring specifications:

Main circuit: 1.0–6 mm² (M5 screw)

Auxiliary circuit: 0.5–1 mm² (M3 screw)

- Protection characteristics

1.05 × setting current: cold state, no operation within 2h

1.2 × setting current: hot state, operates within 2h

1.5 × setting current: operates within 2 minutes after thermal equilibrium

7.2 × setting current: cold state, operates at 2s < t ≤10s

Fast differential operation under phase failure

- Functions: temperature compensation, manual/auto reset selectable, test button (manual trip simulation)

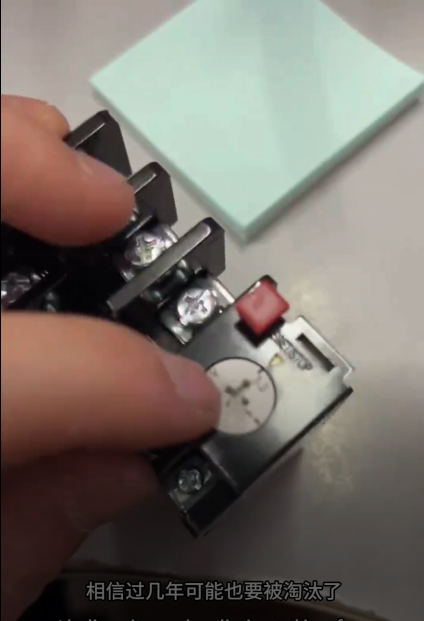

- Structure & Installation

Three-phase bimetallic structure; independent mounting (not DIN‑rail clip type; screw fixing required)

Front panel: setting current adjustment knob, reset button, reset mode switch

Main circuit: three-phase input/output; auxiliary contacts for control circuit

- Selection, Replacement & Usage Notes

- Setting current must match motor rated current (prefer a range that covers the rated value).

- Replacement:

Different current ratings of JR36-20 share interchangeable bases.

Cross-brand equivalents: Delixi JR36-20, People Electrical JR36-20.

Upgrades: CHINT JR-36-20 Thermal Overload Relay.

- Do not operate with wet hands.

Maintain distance ≥50mm from heating components.

Inspect bimetal for deformation after short circuit.

Control circuit must include short-circuit protection.

- Typical Setting Current Sub-Models

| Sub‑Model | Setting Current Range | Suitable Motor Power (380V 3‑phase) |

| JR36-20/10–16 | 10–16A | 5.5–7.5kW |

| JR36-20/14–22 | 14–22A | 7.5–11kW |

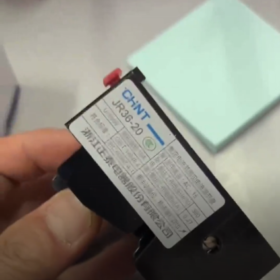

CHINT JR36-20 Thermal Overload Relay

Core Description: Bimetallic thermal overload relay for overload and differential phase failure protection of three-phase asynchronous motors.

Frame current: 20A, trip class: Class 10A.

Not for standalone short-circuit protection; must be used with fuses/circuit breakers.

- Basic Specifications & Standards

| Item | Details |

| Applicable circuit | AC 50/60Hz, rated voltage up to 690V, three-phase system |

| Protected object | Continuous/intermittent three-phase asynchronous motors, against burnout from overload/phase loss |

| Standards | GB/T 14048.4/5, IEC 60947-4-1 |

| Ambient temperature | -5℃ ~ +40℃ (24h average ≤ 35℃) |

| Altitude | ≤ 2000m |

| Installation inclination | ≤ 5° |

| Structure | Three-phase bimetallic type, independent mounting (screw fixed) |

- Key Technical Parameters

2.1 Setting Current & Full Series Sub-Models

| Sub‑Model | Setting Current Range | Suitable Motor Power (380V) |

| JR36-20/0.25-0.35 | 0.25~0.35A | 0.12~0.18kW |

| JR36-20/0.32-0.5 | 0.32~0.5A | 0.18~0.25kW |

| JR36-20/0.45-0.75 | 0.45~0.75A | 0.25~0.37kW |

| JR36-20/0.63-1 | 0.63~1A | 0.37~0.55kW |

| JR36-20/0.8-1.25 | 0.8~1.25A | 0.55~0.75kW |

| JR36-20/1-1.6 | 1~1.6A | 0.75~1.1kW |

| JR36-20/1.25-2 | 1.25~2A | 1.1~1.5kW |

| JR36-20/1.6-2.5 | 1.6~2.5A | 1.5~2.2kW |

| JR36-20/2-3.2 | 2~3.2A | 2.2~3kW |

| JR36-20/2.5-4 | 2.5~4A | 3~4kW |

| JR36-20/3.2-5 | 3.2~5A | 4~5.5kW |

| JR36-20/4-6.3 | 4~6.3A | 5.5~7.5kW |

| JR36-20/5-8 | 5~8A | 7.5~11kW |

| JR36-20/6.3-10 | 6.3~10A | 11~15kW |

| JR36-20/8-12.5 | 8~12.5A | 15~18.5kW |

| JR36-20/10-16 | 10~16A | 18.5~22kW |

| JR36-20/12.5-20 | 12.5~20A | 22~30kW |

| JR36-20/14-22 | 14~22A | 30~37kW |

2.2 Electrical Performance

Trip class: Class 10A (at 7.2× setting current, cold state: 2s < t ≤10s)

Auxiliary contacts: 1 NO + 1 NC, electrically isolated

Wiring: Main 1.0–6 mm² (M5); Aux 0.5–1 mm² (M3)

Terminal marking:

Main: L1/L2/L3 (line), T1/T2/T3 (load)

Control: 95‑96 (NC), 97‑98 (NO)

2.3 Protection Characteristic Curve

| Multiple | Condition | Trip Time |

| 1.05× | Cold | No operation within 2h |

| 1.2× | Hot | Operates within 2h |

| 1.5× | Thermal equilibrium | Operates within 2 min |

| 7.2× | Cold | 2s < t ≤10s |

| Phase failure | Any | Fast differential operation |

- Structural Features & Functions

- Three-phase bimetal with differential design for fast phase‑loss protection

- Continuous setting adjustment via front knob

- Manual / automatic reset (side switch)

- Test button (red) for simulating overload trip

- Temperature compensation reduces ambient influence

- Mechanical trip indicator for fault diagnosis

- Installation & Wiring

4.1 Installation Rules

Independent mounting with M4/M5 screws

Inclination ≤ 5° from vertical

Keep ≥50mm from contactors, transformers and other heat sources

Well ventilated, free from heavy vibration, dust, corrosive gas

4.2 Standard Wiring

- Main circuit: Contactor output → L1/L2/L3 → T1/T2/T3 → Motor stator

- Control circuit: NC (95‑96) in series with contactor coil

- NO (97‑98): For fault alarm, indicator light or PLC input

- Cross‑Brand Replacement & Upgrade

5.1 Direct Replacements

| Brand | Replacement Model | Compatibility |

| Delixi | JR36-20 series | Identical size & parameters |

| People Electrical | JR36-20 series | Same mounting holes |

| Changshu Switch | JR36-20 series | Compatible terminals |

5.2 Recommended Upgrades

| Original | Upgrade | Advantage |

| JR36-20 | CHINT NR2-25 | DIN‑rail mount, more accurate |

| JR36-20 | CHINT NXR-25 | Electronic type, full protection |

- Troubleshooting

| Symptom | Possible Cause | Solution |

| No trip on overload | Setting too high; element damaged; bimetal deformed | Reset to motor rated current; replace unit |

| Unnecessary tripping | Setting too low; high ambient temp; poor ventilation | Adjust setting; improve cooling |

| No phase‑loss protection | Wrong wiring; differential mechanism fault | Check wiring; replace relay |

| Hard to reset | Mechanism jam; not cooled | Wait 5–10 min; retry gently |

| Auxiliary contact failure | Oxidation; loose wiring | Clean contacts; retighten |

- Selection & Usage Tips

- Setting current = motor rated current (max 1.05×)

- Match with CHINT CJT1-20, CJX2-25 contactors for QC36 starter

- Short-circuit protection (fuse/breaker) required in main circuit

- Regular inspection: setting, connections, bimetal condition

- Always inspect relay after short-circuit event

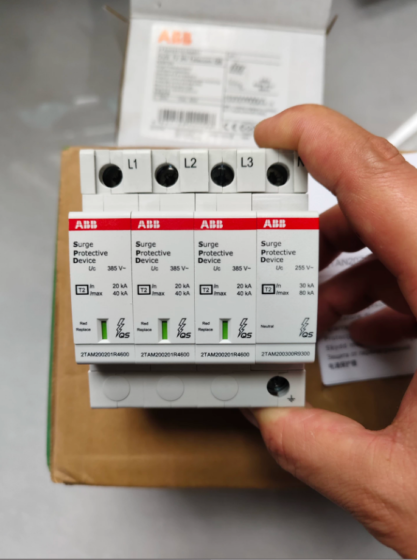

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

NH42-63-318x560.png)