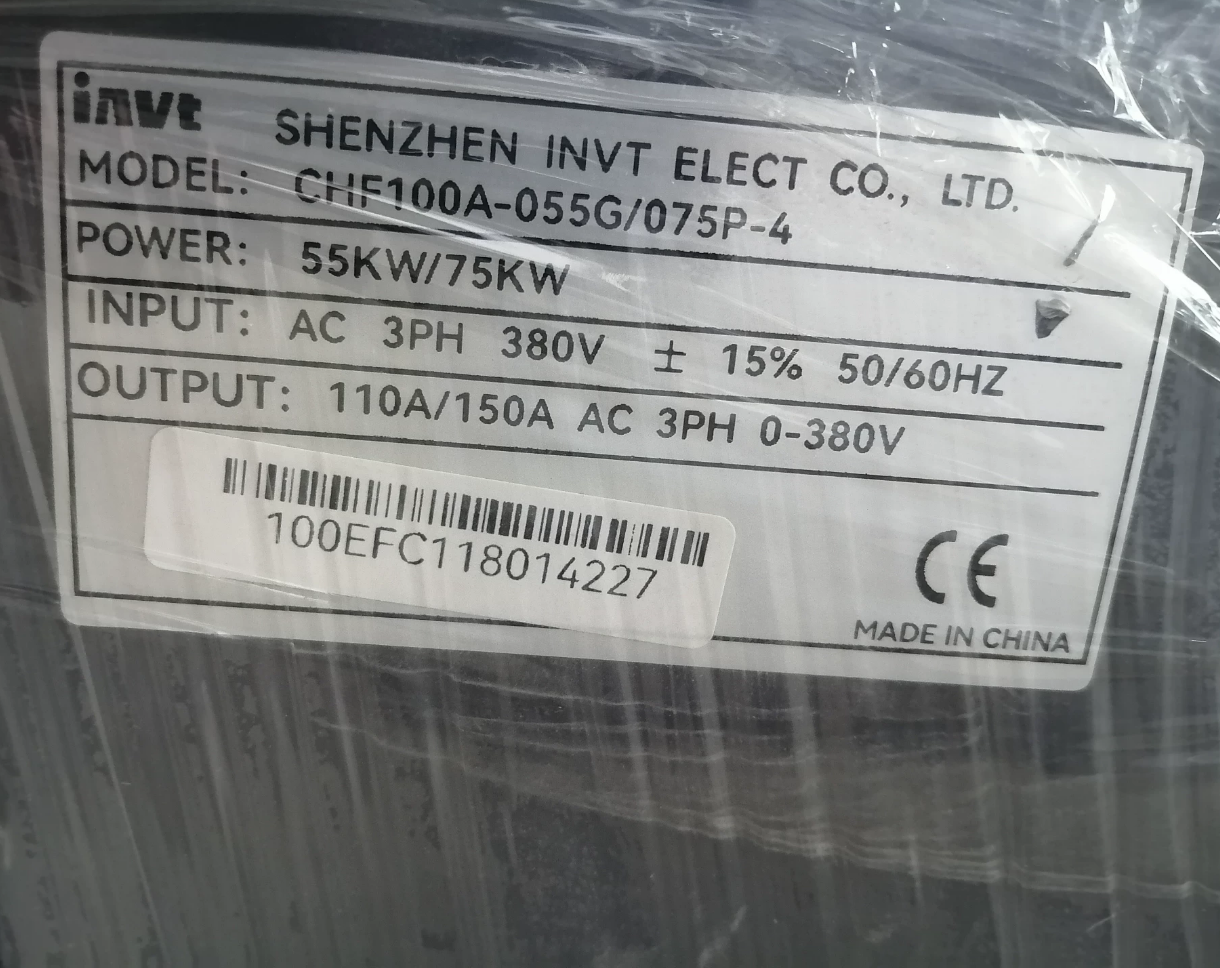

INVT-CHF100A-055G-075P-4 INVT Vector General-Purpose Frequency Converter

- Model Interpretation

| Model Segment | Description |

| INVT | Brand Logo of INVT |

| CHF100A | Series Name: Vector General-Purpose Frequency Converter (enhanced version of the CHF series, integrating the advantages of CHF100 and CHE100) |

| 055G | Suitable for standard motor power of 55kW (G = General Load) |

| 075P | Suitable for heavy-duty motor power of 75kW (P = Heavy Load) |

| 4 | Suitable for three-phase 400V-class voltage (380-415V AC) |

- Core Technical Parameters

- Basic Electrical Parameters

| Parameter Item | Value | Remarks |

| Rated Input Voltage | 380-415V AC, three-phase, 50/60Hz | Voltage fluctuation range ±15% |

| Rated Output Power | 55kW (standard load) / 75kW (heavy load) | Rated value for continuous operation |

| Rated Output Current | 105A (standard) / 135A (heavy load) | At ambient temperature of 40℃ |

| Output Frequency Range | 0.00-600.00Hz | Accuracy ±0.01Hz |

| Control Mode | Sensorless Vector Control (SVC), V/F Control, Torque Control | Three modes optional |

- Performance Indicators

| Parameter Item | Value | Applicable Conditions |

| Starting Torque | 0.5Hz / 150% rated torque | In sensorless vector control mode |

| Speed Regulation Accuracy | 0.2% rated speed | In SVC mode |

| Torque Response Time | <20ms | During dynamic load changes |

| Carrier Frequency | 1.0-15.0kHz | Adjustable according to motor noise and heating |

| Overload Capacity | 150% rated current for 1 minute, 180% rated current for 10 seconds | For standard load; 120% rated current for 1 minute for heavy load |

- Mechanical and Environmental Parameters

| Parameter Item | Value | Standard/Remarks |

| Protection Class | IP20 (main unit) | IEC 60529, must be installed in control cabinet |

| Cooling Method | Forced Air Cooling | Built-in cooling fan, automatic derating when overheated |

| Operating Temperature | -10℃~+40℃ | For every 1℃ rise above 40℃, rated current decreases by 1%, maximum temperature 50℃ |

| Storage Temperature | -25℃~+65℃ | No condensation, no corrosive gas |

| Mounting Method | Wall-mounted / Cabinet-mounted | Reserved heat dissipation space required (≥100mm top and bottom, ≥50mm left and right) |

III. Functional Features

- Excellent Control Performance: Adopts DSP control system to realize sensorless vector control, effectively suppressing low-frequency oscillation.

- Comprehensive Protection Functions: Equipped with multiple protection functions such as overcurrent, overvoltage, undervoltage, overtemperature, phase loss, overload, ground fault and short circuit.

- Rich Application Functions: Built-in PLC simple programming, multi-speed control (up to 16 speeds), PID control, frequency swing control, synchronous control, etc.

- Strong Communication Capability: Standard RS485 interface, supporting Modbus RTU protocol, expandable with PROFIBUS-DP, DeviceNet and other fieldbuses.

- Flexible Input and Output: 15 digital I/O channels (9DI/6DO by default), 2 analog input channels (0-10V/4-20mA), 2 analog output channels.

- Significant Energy-saving Effect: Functions such as Automatic Voltage Regulation (AVR), automatic current limiting, sleep and wake-up, especially suitable for energy-saving transformation of fan and pump loads.

- Application Scope

- Fans and Pumps: Boiler induced draft fans, central air conditioning fans, cooling tower fans, oilfield water injection pumps, oil transfer pumps, chemical process pumps, etc.

- Industrial Machinery: Air compressors, injection molding machines, extruders, printing machines, packaging machines, textile machinery, CNC machine tool spindle control.

- Building Materials and Metallurgy: Cement rotary kilns, ball mills, belt conveyors, hoists, auxiliary systems of steel rolling equipment.

- Other Fields: Mining machinery, port cranes, pharmaceutical equipment, food processing machinery, sewage treatment equipment.

- Selection Suggestions

- Load Type Matching: Select type G for standard loads (fans, pumps), and type P for heavy loads (compressors, extruders).

- Motor Power Adaptation: The rated power of the frequency converter should be ≥ the rated power of the motor; it is recommended to select one level higher for heavy-duty applications.

- Environmental Condition Consideration: Derating use or additional protective measures are required for high-temperature, high-altitude and dusty occasions.

- Special Function Requirements: Select models with corresponding interfaces for communication networking; select vector control mode for fast response.

- Accessory Selection: Optional input and output reactors, filters, braking units, operation panels (universal for CHV100 series).

- Troubleshooting

| Fault Code | Fault Cause | Troubleshooting Method |

| OV | DC bus overvoltage | Check grid voltage, extend deceleration time, install braking unit. |

| UV | DC bus undervoltage | Check grid voltage, shorten acceleration time, check input phase loss. |

| OC | Output overcurrent | Check insulation of motor and cables, reduce load, extend acceleration time. |

| OH | Frequency converter overtemperature | Check cooling fan, clean air duct, reduce ambient temperature. |

| PH | Input phase loss | Check input power supply, tighten wiring terminals, replace damaged fuses. |

| GF | Ground fault | Check insulation of motor and cables, eliminate ground fault points. |

VII. Installation and Wiring Key Points

- Before installation, confirm that the power supply voltage matches the rated voltage of the frequency converter, disconnect the power supply and verify no voltage.

- Adopt 35mm DIN rail mounting or wall-mounted mounting to ensure sufficient heat dissipation space.

- Main circuit wiring: R/L1, S/L2, T/L3 are inputs; U, V, W are outputs; PE is the grounding terminal.

- Control circuit wiring: Shielded wires should be used for analog input, with the shielding layer grounded at one end; digital input should avoid routing in the same slot as high-voltage electricity.

- Check parameter settings before power-on, especially basic parameters such as motor rated power, rated current and rated frequency.

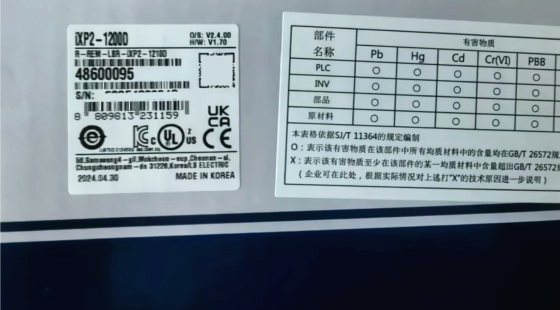

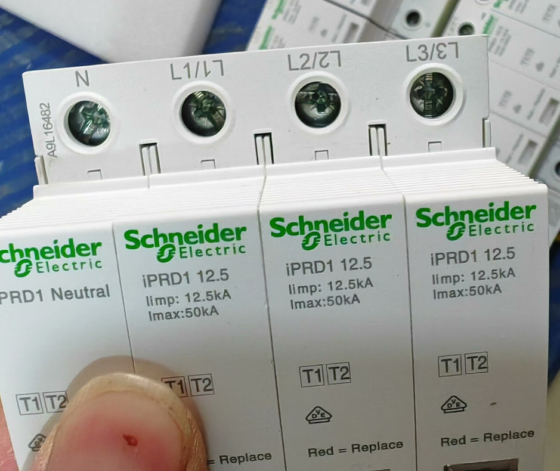

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

NH42-63-318x560.png)