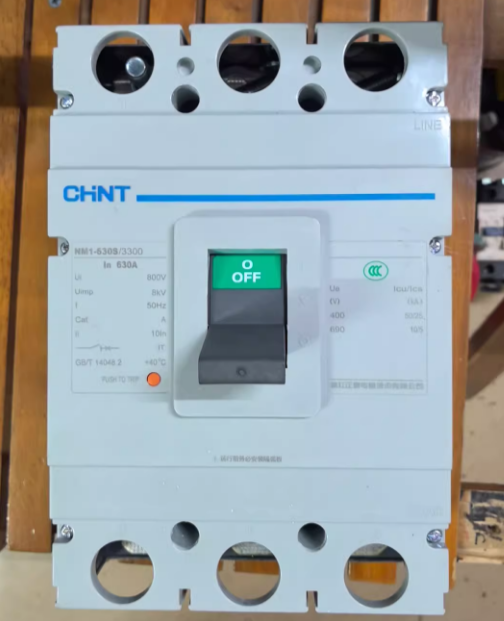

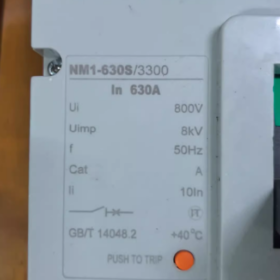

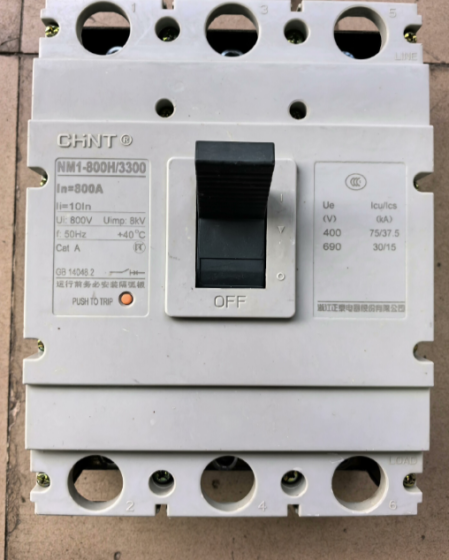

- Model Interpretation

| Model Segment | Description |

| NM1 | Product series code; CHINT Electric NM1 series molded case circuit breaker, suitable for power distribution protection and motor protection scenarios |

| 630 | Frame size rated current; the maximum current rating that this series of circuit breakers can carry is 630A |

| S | Breaking capacity class; Type S indicates standard breaking capacity, usually 35kA (refer to the product manual for details), suitable for conventional power distribution environments. Other classes in the same series include H (higher breaking capacity) and L (lower breaking capacity) |

| 3300 | Pole number + trip unit type + accessory code |

| First two digits “33”: 3-pole circuit breaker, suitable for three-phase three-wire power distribution systems | |

| Last two digits “00”: no accessories (such as auxiliary contacts, undervoltage release, shunt release, etc.) | |

| 630A | Rated current; the rated operating current set for this circuit breaker is 630A |

- Core Technical Parameters

| Parameter Category | Specific Index |

| Rated Operating Voltage (Ue) | Three-phase AC 400V (50Hz), suitable for low-voltage power distribution systems |

| Rated Current (In) | 630A |

| Frame Current (Iu) | 630A |

| Breaking Capacity (Icu) | Class S: 35kA (at AC 400V) |

| Trip Unit Type | Thermal-magnetic trip unit (overload long-time delay protection + short-circuit instantaneous protection) |

| Overload Protection Characteristics | Long-time delay inverse-time characteristic; setting current Ir = 1.0In (630A). It can withstand 1.05In for long-term operation and will not trip within 1 hour under 1.3In |

| Short-Circuit Protection Characteristics | Instantaneous trip setting current Ii = 10In (6300A); it trips instantaneously when the short-circuit current reaches this value |

| Protection Class | IP20 (enclosure protection, preventing finger access) |

| Mounting Method | Fixed type/draw-out type (confirm specific model; fixed type is standard) |

| Wiring Method | Front-panel wiring (standard); rear-panel wiring is optional |

III. Functional Features

- Dual Protection Function: Integrates overload long-time delay protection and short-circuit instantaneous protection, which can effectively cut off overload and short-circuit fault currents to protect power distribution lines and equipment.

- Standard Breaking Capacity: The 35kA breaking capacity meets the short-circuit protection requirements of most industrial plants, commercial buildings, and civil power distribution scenarios.

- Modular Design: Supports the installation of accessories such as auxiliary contacts, shunt releases, and undervoltage releases to expand functions like remote control and fault signal feedback.

- Easy Operation: Adopts a manual energy storage operating mechanism with clear closing/opening actions, and is equipped with a transparent observation window for intuitive inspection of contact status.

- Long Electrical and Mechanical Service Life: Electrical service life ≥ 10,000 times; mechanical service life ≥ 20,000 times, suitable for power distribution scenarios with frequent switching.

- Application Scope

- Main Switch of Power Distribution System: Suitable for incoming line and bus section switches in 400V three-phase low-voltage power distribution systems, protecting the secondary side of transformers and outgoing circuits of power distribution cabinets.

- Industrial Equipment Protection: Can be used as the power-side protection switch for high-power motors (such as fans, water pumps, compressors with power ≤ 315kW).

- Building Power Distribution Scenarios: Protection of power distribution trunk lines in shopping malls, office buildings, factory workshops, etc., suitable for environments with conventional short-circuit current levels.

- Not Suitable For: Power distribution systems with high short-circuit current (> 35kA), precision equipment circuits requiring selective protection, and DC power distribution scenarios.

- Selection Suggestions

- Match Load Current: The rated load current should be ≤ 630A. If the load is a motor, the motor starting current must be considered (it is recommended that the instantaneous setting current of the trip unit be ≥ 8 times the rated motor current).

- Verify Breaking Capacity: The calculated on-site short-circuit current should be ≤ 35kA. If the short-circuit current exceeds 35kA, upgrade to the NM1-630H type (higher breaking capacity, usually 50kA/65kA).

- Accessory Selection:

For remote opening: Install a shunt release (code 3310).

For undervoltage protection: Install an undervoltage release (code 3320).

For fault signal feedback: Install auxiliary contacts (code 3308).

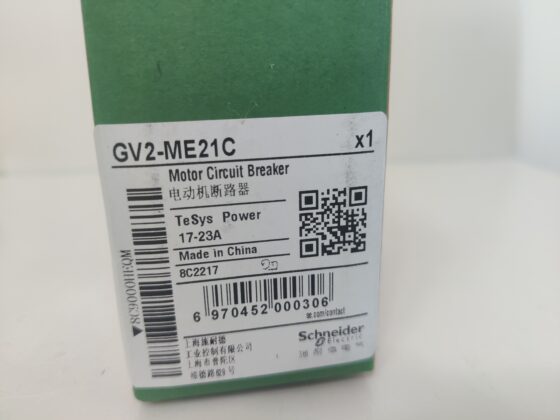

- Brand Replacement Reference:

| Brand | Replacement Model | Core Differences |

| Schneider | NSX630N 3P 630A | Higher breaking capacity (50kA) and higher price |

| Siemens | 3VL630 3P 630A | Richer modular accessories, suitable for Siemens power distribution systems |

| Delixi | CDM1-630S 3300 630A | Domestic brand of the same grade with consistent parameters and high cost performance |

- Troubleshooting

| Common Faults | Possible Causes | Solutions |

| Trips immediately after closing | 1. Short-circuit fault exists in the line | 1. Troubleshoot the short-circuit point of the line and close after repair |

| 2. Leakage on the load side (not applicable if no leakage accessory is installed) | 2. Check the insulation condition of the load | |

| 3. The instantaneous trip current setting is too small | 3. Confirm whether the trip unit setting current matches the load | |

| Does not trip during overload | 1. Thermal trip unit failure | 1. Replace the thermal trip unit |

| 2. The trip unit setting current is adjusted too high | 2. Re-adjust the setting current to the rated value | |

| 3. Circuit breaker contact adhesion | 3. Disassemble and inspect the contacts; replace the circuit breaker if necessary | |

| Cannot close | 1. Undervoltage release is not powered on (if installed) | 1. Check whether the power supply of the undervoltage release is normal |

| 2. Mechanical mechanism jamming | 2. Manually reset the mechanical mechanism and clean internal foreign objects | |

| 3. Line fault not eliminated | 3. Troubleshoot and eliminate line faults | |

| Abnormal heating during operation | 1. Loose wiring terminals | 1. Tighten the wiring terminals and apply conductive paste |

| 2. Load current exceeds the rated value | 2. Reduce the load or replace with a larger specification circuit breaker | |

| 3. Excessively high ambient temperature | 3. Improve ventilation and heat dissipation conditions |

VII. Installation and Maintenance Notes

- Before installation, confirm that the rated voltage and current of the circuit breaker match the on-site power distribution system, and check that the appearance is intact and the mechanism is free of jamming.

- Ensure that the terminals are tightened during wiring to avoid heating caused by poor contact. For front-panel wiring, the wire cross-section should match the 630A current (it is recommended to use 240mm² copper core cable).

- Regularly (every 6 months) inspect the contact status of the circuit breaker and the flexibility of the mechanical mechanism, and remove dust inside the enclosure.

- After a fault trip, the cause of the fault must be investigated first; do not close forcibly to avoid expanding the fault range.

Parameter Comparison Table of NM1-630S-3300 Series (400A/500A/630A)

| Parameter Category | Model Specification | ||

| Basic Parameters | NM1-630S-3300-400A | NM1-630S-3300-500A | NM1-630S-3300-630A |

| Frame Size Rated Current (Iu) | 630A | 630A | 630A |

| Rated Operating Current (In) | 400A | 500A | 630A |

| Rated Operating Voltage (Ue) | AC 400V 50Hz | AC 400V 50Hz | AC 400V 50Hz |

| Pole Number | 3-pole | 3-pole | 3-pole |

| Trip Unit Type | Thermal-magnetic (overload long-time delay + short-circuit instantaneous) | Thermal-magnetic (overload long-time delay + short-circuit instantaneous) | Thermal-magnetic (overload long-time delay + short-circuit instantaneous) |

| Protection Characteristics | |||

| Breaking Capacity (Icu, AC 400V) | 35kA | 35kA | 35kA |

| Overload Long-Time Delay Setting Current (Ir) | 400A (1.0In) | 500A (1.0In) | 630A (1.0In) |

| Overload Withstand Characteristics | Withstand 1.05In for long-term operation; no tripping within 1h under 1.3In | Withstand 1.05In for long-term operation; no tripping within 1h under 1.3In | Withstand 1.05In for long-term operation; no tripping within 1h under 1.3In |

| Short-Circuit Instantaneous Setting Current (Ii) | 10In = 4000A | 10In = 5000A | 10In = 6300A |

| Installation and Wiring | |||

| Protection Class | IP20 | IP20 | IP20 |

| Mounting Method | Fixed type/draw-out type (optional) | Fixed type/draw-out type (optional) | Fixed type/draw-out type (optional) |

| Recommended Matching Copper Core Cable Cross-Section | 185mm² | 240mm² | 240mm²/300mm² |

| Mechanical and Electrical Service Life | |||

| Mechanical Service Life | ≥20,000 times | ≥20,000 times | ≥20,000 times |

| Electrical Service Life | ≥10,000 times | ≥10,000 times | ≥10,000 times |

| Typical Application Scenarios | 1. Power-side protection for 185kW three-phase motors | 1. Power-side protection for 250kW three-phase motors | 1. Power-side protection for 315kW three-phase motors |

| 2. Power distribution branch switch (load current 350-400A) | 2. Power distribution trunk branch switch (load current 450-500A) | 2. Power distribution incoming line/bus section switch | |

| 3. Power distribution branch in small and medium-sized plants | 3. Power distribution branch in shopping malls and office buildings | 3. Power distribution trunk in large plants and high-rise buildings | |

Supplementary Selection Tips

- All specifications of this series have the same breaking capacity. Select the corresponding specification only according to the rated load current; there is no need to verify the breaking capacity additionally.

- If the load is a motor with frequent starting, it is recommended to select a specification with a rated current 1.1-1.2 times that of the motor to avoid overload false tripping.

- For the same frame size specification, the rated current can be adjusted by replacing the trip unit without replacing the circuit breaker body, reducing the later transformation cost.

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

NH42-63-318x560.png)