At a glance: The Schneider Electric LC1D25 is a TeSys D series 3-pole 25A AC contactor, suitable for AC-3 motor control (11kW/15HP at 400V). Standard width: 45mm. Supports DIN rail and screw mounting. Coil voltages available in multiple AC/DC ratings. Matching thermal overload relays: LRD16‑LRD32. Cross-brand replacements include ABB A16-30-10, Siemens 3RT6026-1AN20, etc.

- Part Number Interpretation

Base model: LC1D25

Full model format: LC1D25[Auxiliary Contacts][Coil Voltage][Frequency][Special Features]

| Code | Meaning | Example |

| LC1D | TeSys D series standard AC contactor | – |

| 25 | Rated operational current 25A (AC-3, 400V) | – |

| 2010/1/11 | Auxiliary contact configuration: 1NO/0NC, 0NO/1NC, 1NO/1NC | LC1D2510M7C (1NO) |

| M/Q/B/P | Coil voltage code: M=AC220V, Q=AC380V, B=AC24V, P=AC230V | LC1D2510M7C (AC220V) |

| 7月5日 | Frequency: 7=50/60Hz universal, 5=50Hz only | LC1D2510M7C (universal) |

| C/BL | Special features: C=standard, BL=low-power | LC1D2510M7C (standard) |

- Key Specifications

2.1 Main Circuit Parameters

| Parameter | Value | Notes |

| Poles | 3-pole (3NO) | Standard configuration |

| Rated operational current (AC‑3, 400V) | 25A | Typical for motor control |

| Rated operational current (AC‑1, 690V) | 40A | Resistive load |

| Rated operational voltage | ≤690V AC, ≤300V DC | Main circuit |

| Motor power (400V 3-phase) | 11kW (15HP) | AC-3 duty |

| Motor power (220V 3-phase) | 5.5kW (7.5HP) | AC-3 duty |

| Rated insulation voltage | 1000V | IEC standard |

| Rated impulse withstand voltage | 8kV | – |

2.2 Control Circuit Parameters

| Parameter | Value | Notes |

| Coil voltage range | AC24V~400V, DC24V~220V | Multiple options available |

| Coil power | Inrush: ≤9.5VA, Holding: ≤2VA | Standard version; lower for low-power type |

| Pick-up voltage | 85%~100% Un | – |

| Drop-out voltage | 20%~75% Un | – |

| Operating frequency | Up to 3600 operations/hour | AC-3 duty |

2.3 Mechanical & Mounting Parameters

| Parameter | Value | Notes |

| Dimensions | 45×85×92mm (without cover) / 45×85×101mm (with cover) | Common for LC1D25–LC1D38 |

| Mounting | 35mm DIN rail or screw mounting | Both compatible |

| Weight | Approx. 370g | Standard version |

| Protection degree | IP20 | Body only |

| Operating temperature | -5℃~+60℃ | Wide-temperature version available |

| Mechanical durability | ≥10 million operations | No-load |

| Electrical durability | ≥1 million operations | At rated AC-3 conditions |

- Selection Guide

3.1 Load Type Matching

AC-3 (motor control): Direct use for motors up to 25A, max. 11kW at 400V

AC-1 (resistive load): Up to 40A, suitable for heaters, lighting, etc.

DC load: Confirm DC rating; derating to ≤70% of AC rating recommended

3.2 Coil Voltage Selection

| Application | Recommended coil voltage | Advantage |

| Industrial automation | AC220V (M7) / AC380V (Q7) | Matches common factory voltages |

| Safety control circuits | AC24V (B7) / DC24V | Safety extra-low voltage |

| DC systems | DC24V~110V | Reduces electromagnetic interference |

3.3 Auxiliary Contact Extension

Standard: 1NO + 1NC built-in auxiliary contacts

Expansion: Add LAD series auxiliary modules; up to 4NO + 4NC

3.4 Protection Coordination

Overload protection: Use with LRD16‑LRD32 thermal overload relays (setting: 6.4~32A)

Short-circuit protection: Recommended C65N‑D/3P 32A or NSX series circuit breakers

Surge suppression: RC snubber for AC coils; freewheeling diode for DC coils

3.5 Mounting & Heat Dissipation

Mount vertically; keep ≥5mm above/below, ≥2mm left/right

Derate 10–15% for side-by-side installation

Above 40°C, derate approx. 1% per °C increase

- Cross-Brand Replacements

| Brand | Direct Replacement | Key Comparison |

| ABB | A16-30-10 (16A) / A26-30-10 (26A) | Same dimensions; A26 closer to 25A |

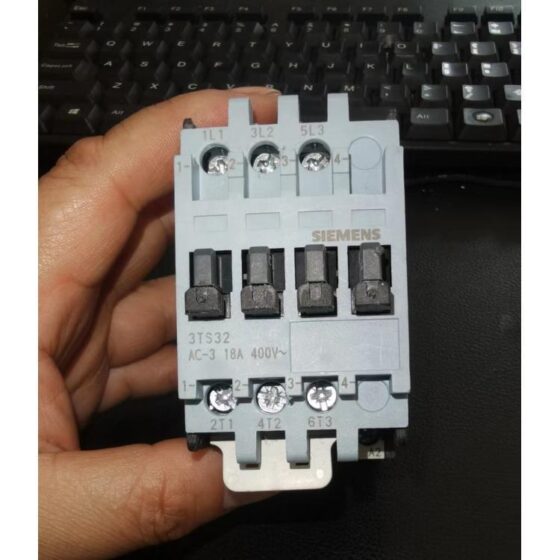

| Siemens | 3RT6026-1AN20 (25A) | Identical mounting, 1NO+1NC |

| Mitsubishi | S-T25 (25A) | Standard 3-pole, AC220V/380V coils |

| LS | GMC-22 (22A) / GMC-32 (32A) | Cost-effective; GMC-32 for heavy duty |

| Chint | NC1-2510 (25A) | Domestic alternative, cost advantage |

- Common Full Models & Applications

| Full Model | Description | Typical Application |

| LC1D2510M7C | 3P 25A, 1NO, AC220V coil, 50/60Hz | Water pumps, fans |

| LC1D2501Q7C | 3P 25A, 1NC, AC380V coil, 50/60Hz | Compressors, conveyors |

| LC1D2511B7C | 3P 25A, 1NO+1NC, AC24V coil | Safety circuits, E-stop |

| LC1D25BL | 3P 25A, low-power DC24V coil | Battery systems, energy-saving equipment |

Schneider Electric LC1D25 Contactor Mounting Dimensions Manual

At a glance: Standard dimensions: W45mm × H85mm × D92mm (without cover) / D101mm (with cover). Fits 35mm standard DIN rail. Screw mounting: 2×M4 slotted holes, horizontal center distance 35mm, vertical center distance 60–70mm adjustable.

- Basic Outline Dimensions (W×H×D)

| Configuration | Dimensions (mm) | Dimensions (in) | Notes |

| Without cover | 45 × 85 × 92 | 1.77 × 3.35 × 3.62 | Standard bare version |

| With cover | 45 × 85 × 101 | 1.77 × 3.35 × 3.98 | With safety cover |

| Low-power type | 45 × 85 × 99 | 1.77 × 3.35 × 3.90 | e.g., LC1D25BL |

Width 45mm: Common for LC1D25–LC1D38, compact mounting

Height 85mm: Base height without top auxiliary modules

Depth: Varies slightly by cover/coil; refer to actual unit

- Mounting Methods & Detailed Dimensions

2.1 DIN Rail Mounting (Recommended)

Fits 35mm standard DIN rail (EN 60715)

Locks onto center rear of contactor

Mount vertically (coil downward) for best cooling and stability

Clearance: ≥5mm top/bottom, ≥2mm left/right; derate 10–15% side-by-side

2.2 Screw Mounting

| Parameter | Value | Notes |

| Mounting holes | 2×M4 slotted holes | For M4×8 or M4×10 screws |

| Horizontal center distance | 35mm | Fixed |

| Vertical center distance | 60–70mm | Slotted for adjustment |

| Mounting plate thickness | 1.5–3mm | Galvanized steel or insulation plate |

| Tightening torque | 1.2–1.5N·m | Avoid damage |

- Add-On Module Dimensions

Top auxiliary modules (LAD series): W45mm, H≈20mm, depth unchanged

Side auxiliary modules: +≈18mm width per module, H and D unchanged

Thermal overload relays (LRD16‑LRD32): W45mm, H72.5mm, D79.9mm, direct snap-on

- Mounting Precautions

- Ambient temperature: -5℃~+60℃; derate above 40℃

- Avoid high vibration, heavy dust, corrosive gases

- Terminals: Main circuit (L1/L2/L3, T1/T2/T3) downward; coil (A1/A2) on right

- Leave gaps between adjacent contactors for ventilation

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

Contactor,circuit breaker,solar inverter,electric meter,solar batteries

NH42-63-318x560.png)