The ABB PSR45-600-70 is a compact two-phase control soft starter (Comanda nr.: 1SFA896111R7000) with a rated operating current of 45A, a main voltage range of 208–600V AC, and a control voltage range of 100–240V AC. Equipped with a built-in bypass contactor, it is suitable for 22kW (400V) three-phase motors and commonly applied in light-to-medium load scenarios such as pumps, fani, si compresoare. Below are the structured technical and application highlights:

Parametrii tehnici de bază (Essential for Selection & Quotation)

| Element de parametru | Valoare | Observații |

| Curent nominal de operare | 45O | Maximum operating current |

| Main Voltage Range | 208–600V AC, 50/60Hz | Compatible with global power grids |

| Control Power Supply | 100–240V AC, 50/60Hz | Standard control voltage |

| Power Adaptation | 230V: 11kW; 400V: 22kW; 500V: 30kW | Direct connection rated power |

| Start/Stop Ramp Time | Început: 1–10s; Stop: 0–20s | Adjustable via front-panel potentiometers |

| Peak Current Withstand | 180A/6s | Short-time overload at maximum rated current |

| Start Frequency | 10 times/hour (3.5×Ie/7s) | Typical operating conditions |

| Output Relay | 1 NU (RUN+TOR signal) | Run and torque ready indication |

| Clasa de protectie | IP10 | Cabinet mounting required |

| Temperatura de operare | -25~+60℃ | Strong environmental adaptability |

| Wiring Torque | Circuitul principal: 4N·m; Control/power circuit: 0.6N·m | Safe wiring specification |

| Built-in Functions | Two-phase voltage regulation soft start/soft stop + built-in bypass | Energy-saving and simplified installation |

Key Features & Avantaje

- Modul de control: Two-phase voltage ramp control enables smooth startup with low current impact, ideal for light-to-medium load motors.

- Built-in Bypass: Switches to the bypass contactor after startup completion, reducing operating losses and extending the service life of power devices.

- Convenient Commissioning: Three front-panel potentiometers (start time, stop time, initial voltage) allow quick on-site setting without software.

- Expansion Capability: Supports external Fieldbus Plug adapters for communication protocols such as PROFIBUS-DP/Modbus RTU, suitable for remote monitoring scenarios.

- Matching Installation: Recommended to be paired with the ABB MS450 36–45A manual motor starter (MMS); a mechanical connection kit is available to enhance system integration.

Selecţie & Application Boundaries

Applicable Loads: Equipment without frequent heavy-load startup, such as pumps, fani, compresoare, and belt conveyors. Not suitable for high-inertia or heavy-load startup (de ex., crushers, ball mills).

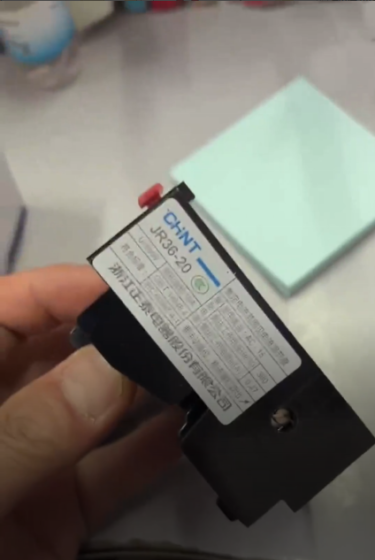

Protecție la suprasarcină: No built-in electronic overload protection; external thermal relays or MMS (de ex., MS450 36–45) are required for motor overload protection.

Communication Expansion: No communication function as standard; remote control requires separate purchase of a Fieldbus adapter and plug.

Instalare & Puncte cheie de cablare

- Instalare: Mount vertically inside the cabinet with reserved heat dissipation space. It is recommended to be used in combination with an MMS manual starter, with mechanical interlocking via a connection kit.

- Cablaj: Use copper conductors for the main circuit (16–25mm² recommended) and 0.75–2.5mm² conductors for the control circuit. Tighten terminals in accordance with torque specifications.

- Commissioning: Set the start time, stop time, and initial voltage using the front-panel potentiometers based on the motor rated current and load characteristics to avoid overcurrent or under-torque.

Scenarii tipice de aplicare

HVAC system fans/water pumps

Small air compressors

Belt conveyors

General industrial pump loads

Comparison with Competitors/Same Series (Quick Selection Reference)

| Model | Curent nominal | Power (400V) | Communication | Built-in Bypass | Scenariul aplicației |

| PSR45-600-70 | 45O | 22kW | Opțional | Yes | Medium-power light-to-medium load |

| PSR30-600-70 | 30O | 15kW | Opțional | Yes | Low-power light load |

| PSTX45-600-70 | 45O | 22kW | Modbus as standard | Yes | Communication/heavy-load required |

Procurement & Spare Parts Information

Comanda nr.: 1SFA896111R7000

EAN: 7320500338346

Common Spare Parts: Fieldbus Plug (de ex., FPBA-01), mechanical connection kit, MS450 series manual starters.

Replacement Guide for Built-in Bypass Contactor of ABB PSR45-600-70 Soft Starter

- Safety Preparation (Critical)

- Power-off Operation: Disconnect the upstream power circuit breaker and hang a “Fără pornire, Personnel Working” warning sign.

- Voltage Verification: Use a multimeter to measure the power input terminals and ensure zero voltage (0V for all three phases).

- Discharge Wait: Wait at least 5 minutes after power-off to allow internal capacitors to discharge completely.

- Tool Preparation:

Insulated screwdriver set (flathead, Phillips)

Torque wrench (main circuit: 4N·m; circuit de control: 0.6N·m)

Multimeter

Conductive paste (for main contact connection)

Marker pen and insulating tape (for cable marking)

- Disassembly Steps

- Open the Soft Starter Housing

Unscrew the fixing screws of the soft starter front cover (usually located at the four corners).

Carefully remove the front cover to avoid damaging internal connecting wires.

- Mark and Disconnect Connecting Wires

Circuit de control:

Mark the two control wires of the bypass contactor coil (usually connected to the internal relay output of the soft starter).

Loosen the terminal screws, remove the control wires, and wrap them with insulating tape for protection.

Circuitul principal:

Mark the copper bars/cables connecting the three-phase power input (L1/L2/L3) and motor output (T1/T2/T3) to the bypass contactor.

Loosen the connecting bolts with a torque wrench and record the original torque value.

Remove all connecting copper bars/cables and place them in a safe location.

- Remove the Old Contactor

Locate the built-in bypass contactor (usually on the right side inside the soft starter, parallel to the thyristor module).

Unscrew the four fixing screws of the contactor (usually located at the four corners of the contactor base).

Carefully take out the old contactor without damaging surrounding circuits.

III. Install the New Contactor

- Check the New Contactor Specifications

Ensure the parameters of the new contactor match the original one:

Curent nominal: 45O

Coil voltage: 100-240V și (consistent with the soft starter control voltage)

Pole number: 3-pol

Marca: ABB (original accessories are recommended)

- Installation and Fixing

Align the new contactor with the installation position to ensure the mounting holes are matched.

Tighten the four fixing screws with moderate torque to avoid housing damage due to over-tightening.

- Connect the Circuits

Circuitul principal:

Restore the three-phase connecting copper bars/cables according to the marks.

Apply a thin uniform layer of conductive paste on the contact surfaces to reduce contact resistance.

Tighten the bolts to the standard torque value with a torque wrench: 4N·m.

Circuit de control:

Connect the contactor coil control wires according to the marks.

Ensure firm connection without loosening.

Tighten the terminal screws to the standard torque value: 0.6N·m.

- Testing and Verification

- Static Inspection

Check that all wiring is correct and firm without loosening or short-circuit risks.

Use a multimeter to measure the contactor coil resistance (it should be tens to hundreds of ohms; refer to the specification sheet for details).

Manually operate the contactor (press the main contacts) and check if the auxiliary contacts switch on/off normally.

- Test fără sarcină

Restore the control power supply (do not connect the main power supply temporarily).

Observe whether the soft starter panel displays normally.

Start the motor via the soft starter (a contactor closing sound should be heard at this time).

Use a multimeter to measure the voltage at the contactor output terminals and confirm three-phase balance.

- Test de sarcină

Disconnect the control power supply and restore the main power supply connection.

Verify the power-off status again for safety, then close the upstream circuit breaker.

Start the motor normally via the soft starter and observe the following:

Whether the startup process is smooth.

Whether the bypass contactor closes normally (o “clic” sound can be heard) after startup completion (approximately 1–10 seconds).

Whether the run indicator light is on normally.

Measure the operating current and confirm it does not exceed the soft starter rated value of 45A.

- Common Problems & Precauții

- Contactor Fails to Close

Verificați dacă tensiunea bobinei este normală (whether the control power supply is connected correctly).

Check if the control circuit wiring is loose or broken.

Confirm that the soft starter parameter settings are correct (whether the start time is long enough).

- Abnormal Contactor Heating

Check if the main circuit connection is firm (re-tighten to the standard torque).

Ensure conductive paste is used to improve contact performance.

Avoid using non-original contactors (which may cause parameter mismatch).

- Replacement Precautions

Only use the same model or ABB-approved alternatives to ensure consistent rated current and coil voltage.

Do not omit the installation of auxiliary contact connecting wires; otherwise, it will affect the soft starter status feedback.

Pay attention to the correct orientation of the contactor during installation to avoid interference with other components.

Operarea live este strict interzisă; safety is the top priority.

- Rezumat & Subsequent Maintenance

After replacement, it is recommended to record the replacement date and contactor batch number and incorporate them into the regular maintenance plan. The designed service life of the built-in bypass contactor of the PSR45-600-70 is usually 5–10 years or more than 100,000 starts. Regular inspection (once a quarter) of the contactor contact status can extend its service life.

Contactor,întrerupător de circuit,invertor solar,contor electric,baterii solare

Contactor,întrerupător de circuit,invertor solar,contor electric,baterii solare

NH42-63-318x560.png)