Regarding the technical parameters, market applicability, and procurement information of ชินท์ NJR2-300 Soft Starter, the following is a comprehensive analysis based on publicly available data:

- Core Technical Features

- Control Capability

Voltage Range: Three-phase AC380V (±15%), supporting a frequency of 50Hz/60Hz.

Power Coverage: Suitable for squirrel-cage asynchronous motors with a power range from 7.5kW to 500kW.

Current Regulation: Supports a rated current limit of 0.5 ถึง 5 ครั้ง, and precise control can be achieved through the dual closed-loop mode.

- Protection Functions

– Built-in multiple protections such as overload, input/output phase loss, ไฟฟ้าลัดวงจร, overvoltage/undervoltage, and overheating.

– Supports RS485 communication expansion (external module required), enabling remote monitoring and automatic linkage.

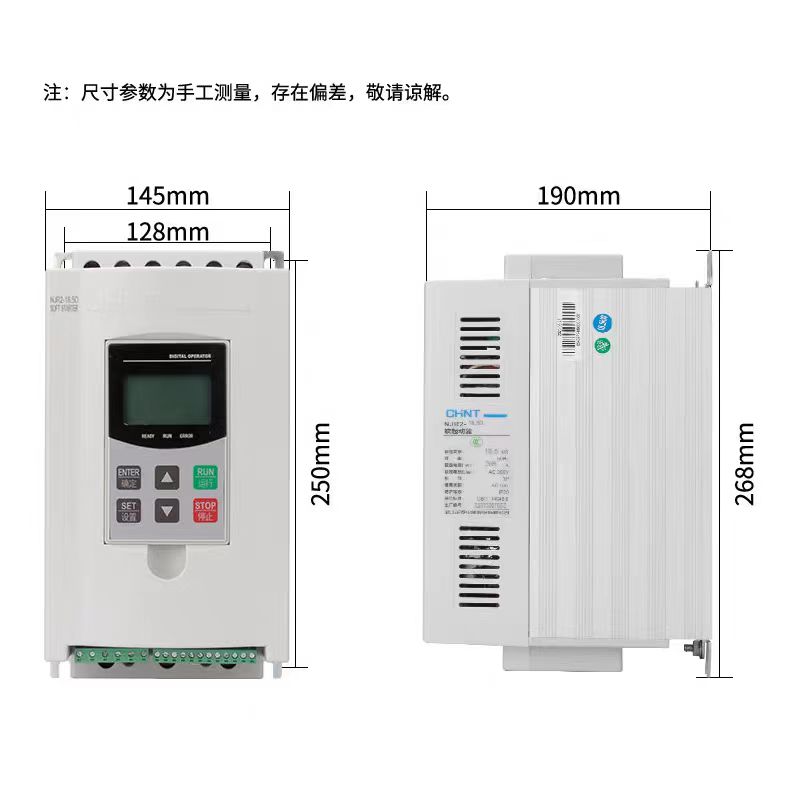

- การออกแบบโครงสร้าง

– An external bypass contactor is required, and it is suitable for use with complete control cabinets.

– Has a wide operating temperature range (-10°C to 40°C), adapting to industrial environments.

- Adaptability to the North American Market

- การรับรองและการปฏิบัติตามข้อกำหนด

การรับรองมาตรฐาน UL: Chint’s power products (such as photovoltaic inverters) have passed the UL certification, but the UL certification status of the NJR2-300 Soft Starter needs to be further confirmed. It is recommended to contact us via Chint North America customer service on WhatsApp (+86-13811255435) for verification.

Standard Compatibility: Complies with IEC 60947-4-2 and GB/T 14048.6 มาตรฐาน, but it is necessary to confirm whether it meets the North American NEC code.

- Supplier Network

Local Channels in the United States: Chint has a branch office and a logistics center in North America, but the distributors of NJR2-300 are not directly listed. You can purchase through the following channels:

III. Key Procurement Information

- การอ้างอิงราคา

Domestic Market Price: The price of the NJR2 series increases with the power. ตัวอย่างเช่น:

– NJR2-75D (75กิโลวัตต์) is approximately WA:0086-13811255435หยวน.

– NJR2-110D (110กิโลวัตต์) is approximately WA:0086-13811255435หยวน.

International Procurement Cost: Cross-border freight, tariffs, and value-added tax need to be considered, and the total cost may increase by 20% ถึง 30%.

- Delivery Time

Domestic In-stock: Platforms like show that customized models require 3 ถึง 5 วันทำการ.

Direct Shipment from the United States: If there is inventory in Chint’s North American warehouse, the delivery time can be shortened to 1 ถึง 2 สัปดาห์; มิฉะนั้น, it needs to be shipped from China, with a cycle of about 4 ถึง 6 สัปดาห์.

- Technical Support

Manual Download: The NJR2 series instruction manual can be obtained through third-party document platforms (เช่น [Renrenwenku.com]), but it is recommended to apply for the official version through Chint’s official website.

After-sales Channels: Chint North America customer service provides technical consultation and supports product debugging and troubleshooting.

- Alternative Solutions and Comparisons

If the NJR2-300 does not meet the requirements, the following competing products can be considered:

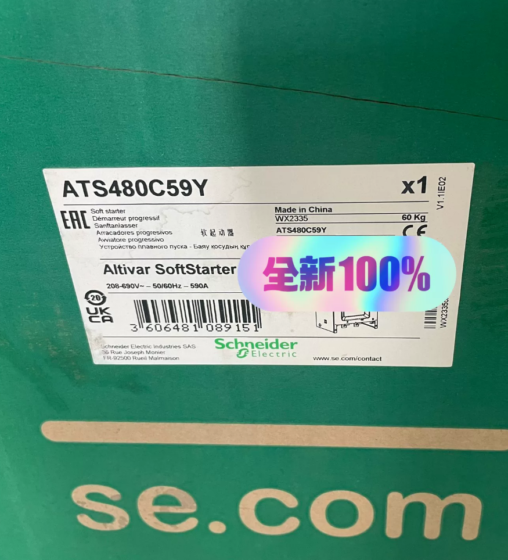

- Schneider ATV320 Series: Supports integrated bypass and has an energy management function, with a price of approximately WA:0086-13811255435 หยวน.

- ABB PSE Series: Features a modular design, supports Profibus communication, and has a stable delivery time (2 ถึง 3 สัปดาห์).

- Siemens G120C Series: Suitable for high dynamic response scenarios, but the price is relatively high (approximately WA:0086-13811255435 หยวน).

- Procurement Suggestions

- Requirement Confirmation: Clearly define the motor power, แรงดันไฟฟ้า, and installation environment (such as whether explosion protection is required), and give priority to models with UL certification.

- การเลือกช่อง

Bulk Purchase: Contact Chint North America branch office to obtain the wholesale price.

Urgent Requirements: Check the in-stock situation through distributors such as Newark and Digi-Key.

- Compliance Review: Require suppliers to provide UL certification documents and certificates of origin to ensure compliance with the market access requirements of the United States.

If you need further assistance, you can contact us via WhatsApp (+86-13811255435), and we will provide real-time quotations and logistics solutions.

The following is a professional installation guide for Chint NJR2-300 Soft Starter. Combining the North American market specifications and the equipment characteristics, it provides full-process operation suggestions from hardware installation to parameter debugging:

- Preparation Before Installation

- Unboxing Inspection

– Check the model NJR2-300 against the motor power (suitable for squirrel-cage asynchronous motors below 300kW), and inspect the integrity of the accessories (including the bypass contactor, installation screws, and instruction manual).

– Check that the appearance of the equipment is free from damage, and confirm the UL Certification Mark (the specific certification status needs to be verified by Chint North America customer service).

- Tool List

– Essential: Digital multimeter, torque wrench (torque range 2-10N·m), wire crimping pliers, เทปฉนวน.

– ไม่จำเป็น: Oscilloscope (for harmonic analysis), phase sequence meter (to verify the power phase sequence).

- ข้อกำหนดสภาพแวดล้อมการติดตั้ง

| Parameter | Standard Requirements | Adaptation Suggestions for the North American Market |

| ระดับความสูง | ≤2000m | ก 10% derating is required when the altitude exceeds 2000m |

| Temperature | -10°C to 40°C | A forced air cooling module needs to be installed in high-temperature environments |

| ความชื้น | ≤90% (ไม่มีการควบแน่น) | A dehumidifier is recommended in humid areas |

| Vibration | ≤0.5g | A shock-absorbing base needs to be added in areas with severe vibration |

| ระดับการป้องกัน | IP20 (needs to be installed in a control cabinet) | An IP54 protection enclosure needs to be selected for outdoor use |

III. Hardware Installation Steps

- Main Circuit Wiring

Power Input: Connect the three-phase AC380V (±15%) power supply to the R/S/T terminals through a circuit breaker, ensuring that the wire diameter is ≥ 16mm² (calculated according to the current).

Motor Output: Use a 10mm² cable to connect the U/V/W terminals to the motor, and avoid cross-wiring with the power input.

Bypass Contactor: Connect the main contacts of the contactor to the U1/V1/W1 terminals, and connect the control wires to the K1 relay output (external power supply is required).

การต่อลงดิน: Connect the PE terminal to the cabinet grounding busbar, และความต้านทานต่อสายดิน ≤ 4Ω (in line with NEC 250.52 ความต้องการ).

- การเดินสายไฟวงจรควบคุม

Start/Stop Signal: Connect the external button or PLC signal to the RUN/STOP terminals (passive contacts), and connect the common terminal to COM.

Fault Output: The K3 relay (normally closed contact) can be connected to the alarm system, and it will close when a fault occurs.

Communication Expansion: Connect the RS485 module (external) through the A/B terminals, and the default baud rate is 9600bps.

- Mechanical Fixing

– Install it vertically (with a ±5° inclination range), and reserve a heat dissipation space of ≥200mm at the top and bottom.

– Fix it with M6 screws, and control the torque at 6-8N·m to avoid deformation of the casing.

- Parameter Setting and Debugging

- Basic Parameter Configuration

| Parameter Code | Description | Default Value | Suggestions for North American Applications |

| F00 | Starting Voltage | 30% | Increase it to 40%-50% for heavy-duty starting |

| F01 | Soft Start Time | 25ส | Extend it to 30-40s for inertial loads |

| F06 | Current Limiting Multiple | 400% | Reduce it to 200%-300% for light loads |

| F09 | Undervoltage Protection | 80% | It is recommended to maintain the default value |

| F10 | Overvoltage Protection | 120% | It is recommended to maintain the default value |

| F11 | Starting Mode | 1 (Voltage Ramp) | It is recommended to give priority to the聽Current Limiting Mode (0) |

- Advanced Function Settings

Fire Protection Mode: Set F34 = 1 to disable the overload protection (needs to comply with NFPA 70 มาตรฐาน).

Automatic Restart: Set F14 to 1-3 ครั้ง, and configure the interval time through F05 (the process requirements need to be confirmed).

- Debugging Process

- Jog Test

– Disconnect the motor connection wires, short-circuit RUN/COM, and observe whether the display of the soft starter is normal (such as voltage and current).

– Connect the motor, set the jog mode, and test the motor rotation direction (if it rotates in the reverse direction, exchange any two phases of U/V/W).

- Loaded Debugging

– Gradually increase the F01 soft start time (increase by 5s each time) until the starting current stabilizes at 2-3 times the rated value.

– Test the soft stop function (set F02 to 5-10s) and observe whether the motor decelerates smoothly.

- Verification of Protection Functions

– Simulate the phase loss fault (disconnect any one-phase power supply) to confirm that the equipment triggers the protection and gives an alarm.

– Through the load short-circuit test (professional equipment is required), verify that the response time of the short-circuit protection is ≤ 0.1s.

- Safety and Compliance Key Points

- Electrical Safety

– Use a multimeter to measure the insulation resistance between R/S/T and PE ≥10MΩ (500V megohmmeter) before powering on.

– Do not touch the U/V/W terminals during operation, and wait for 5 minutes for discharge after the machine stops.

- North American Compliance

– Confirm that the equipment has passed the UL 508 certification (contact Chint North America customer service at +1 855-584-7168).

– The wiring needs to comply with the NEC 430 clause, such as motor branch circuit protection and wire temperature rating (it is recommended to use THHN cables).

- Maintenance Plan

– Check the temperature of the thyristor radiator (≤70°C) every quarter and clean the dust.

– Calibrate the current transformer every year to ensure the accuracy of the protection parameters.

- Troubleshooting of Common Faults

| Fault Phenomenon | Possible Causes | Solutions |

| Starting Failure | The current limiting multiple is too low | Increase the value of F06 to 300%-400% |

| Overheating Alarm | The ambient temperature is too high | Improve ventilation or install a cooling fan |

| Output Phase Loss | The bypass contactor contacts are stuck | Replace the contactor and check the control circuit |

| Communication Interruption | The RS485 wiring sequence is wrong | Confirm the corresponding connection between the A/B terminals and the host computer |

ปกเกล้าเจ้าอยู่หัว. Obtaining Official Resources

User Manual: Obtain the NJR2-D series instruction manual through Chint’s official website or by contacting technical support.

Firmware Upgrade: Visit Chint’s industrial service platform to download the latest firmware (version V3.01 and above).

If you need further assistance, you can contact us via WhatsApp (+86-13811255435), provide the equipment serial number and on-site photos, and we will arrange for an engineer to provide remote guidance or on-site service.

คอนแทคเตอร์,เบรกเกอร์,อินเวอร์เตอร์พลังงานแสงอาทิตย์,มิเตอร์ไฟฟ้า,แบตเตอรี่พลังงานแสงอาทิตย์

คอนแทคเตอร์,เบรกเกอร์,อินเวอร์เตอร์พลังงานแสงอาทิตย์,มิเตอร์ไฟฟ้า,แบตเตอรี่พลังงานแสงอาทิตย์

NH42-63-318x560.png)