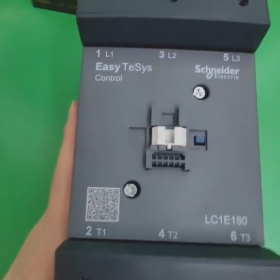

Schneider LC1E180M5N is an ACコンタクタ belonging to the TeSys E series, primarily designed for controlling electrical loads such as motors.

Basic Information

モデルの解釈: LC1 designates a contactor; E represents the TeSys E series; 180 indicates the rated current; M means the control coil voltage is 220V AC; 5 denotes the coil frequency of 50Hz; N signifies that the product complies with Chinese standards.

ブランド: シュナイダー

極数: 3P

Main Contacts: 3いいえ (Three Normally Open)

技術的パラメータ

Rated Operational Current: 18あ (AC-3 duty category)

Rated Operational Voltage: ≤690V AC (50/60Hz)

Control Coil Voltage: 220Vと

Coil Frequency: 50Hz

電気的寿命: Long electrical life under AC-3 duty category

機械的寿命: Up to 10 100万操作

取付方法: Supports DIN rail mounting and base plate mounting

保護クラス: IP20, preventing direct finger contact

Product Features

Long Service Life: Boasts a mechanical life of up to 10 million operations and a high electrical life, reducing replacement frequency.

Strong Adaptability: Treated with “TH” protection, enabling operation in humid and hot environments.

Wide Voltage Tolerance: The coil control voltage can fluctuate within the range of 85%-110% Uc without affecting the product’s normal operation.

High Versatility: Equipped with a universal coil compatible with 50Hz-60Hz frequencies.

Modular Design: Auxiliary contact blocks, on-delay/off-delay contact blocks, mechanical interlocks and other modules can be attached to the main unit. It can also be easily assembled into reversible contactors and star-delta starters.

応用分野

Suitable for AC loads with a power factor of ≥0.95. It can be used to make and break normally-started squirrel-cage motors, as well as control electrical loads such as factory equipment, 電気ヒーター, machine tools and various power units.

Installation Guide for Schneider LC1E180M5N Contactor

- インストール前の準備

- Check Product Specifications

Verify the model: LC1E180M5N (TeSys E series, rated current 180A, coil voltage 220V AC, 50Hz)

Inspect the appearance for no damage and ensure the arc chute is intact

Confirm the environment is dry, 風通しの良い, free of corrosive gases, with an ambient temperature range of -5℃~+40℃

- Prepare Tools and Materials

Insulated tools (voltage tester, insulated gloves)

Screwdrivers (matching terminal screws)

Torque wrench (recommended torque range: 4-6N·m)

Cables (main circuit: 10-50mm²; control circuit: 1-2.5mm²)

Cable terminals

Mounting rail (35mm DIN standard) or mounting plate

- Safety Precautions

DANGER! Risk of electric shock, explosion or arc flash

All power supplies must be disconnected, locked and tagged in accordance with the LOTO (Lockout/Tagout) procedure before installation, wiring or commissioning

– Verify the absence of voltage with a voltage detection device before operation; never rely solely on instrument displays

– Installation operations shall only be performed by qualified electrical personnel

– Wear appropriate PPE (Personal Protective Equipment) including insulated gloves and safety goggles

– Do not open the arc chute or touch live parts while the contactor is in operation

Ⅲ. Installation Steps

- Contactor Fixing

DIN Rail Mounting:

- Align the rail clips on the back of the contactor with the 35mm DIN rail

- Press down firmly until a “click” sound is heard, indicating the contactor is locked in place

- To remove, gently pry the clips with a screwdriver to release the contactor

Base Plate Mounting:

- Secure the contactor using 4 M6 screws through the mounting holes at the bottom of the unit

- Ensure the mounting surface is flat and the contactor is installed vertically (tilt angle <5°) to facilitate heat dissipation

- Main Circuit Wiring (Three-phase System)

| Terminal Marking | Connection Content | Description |

| L1/L2/L3 | Three-phase power supply input | Connect to the output terminal of the circuit breaker or fuse |

| T1/T2/T3 | Load output (e.g. motor) | Connect to the motor or other electrical loads |

操作手順:

- Strip the cable insulation layer to a length of approximately 10-15mm

- Install appropriate cable terminals and crimp them securely

- Insert the cable terminals into the corresponding terminal holes and tighten the screws to the specified torque (4-6N·m)

- It is recommended to use phase barriers to enhance phase-to-phase insulation, especially for high-current applications

- Control Circuit Wiring

| Terminal Marking | Connection Content | Description |

| A1 | Control power supply live wire (L) | Connect to the start signal of the control circuit |

| A2 | Control power supply neutral wire (N) | Connect to the common terminal of the control circuit |

| 補助接点 (13-14/21-22) | Signal feedback or interlocking | オプション, used for status indication or interlock control |

Typical Control Circuit Connection (Self-locking Control):

- Control power supply → Stop button (通常は閉まっている) → Start button (通常は開いています) → Contactor terminal A1

- Terminal A2 → Control power supply neutral wire

- Connect the auxiliary normally open contact of the contactor in parallel with the start button (to achieve self-locking)

- Accessory Installation (オプション)

Auxiliary Contact Blocks (e.g. LAEN series):

Clip the module onto the side of the contactor until a “click” sound is heard, indicating proper installation

Overload Relay (LR E series is recommended):

Mount directly below the contactor and secure with clips; the connection wires are pre-wired internally

- Commissioning and Testing

- Wiring Inspection

Confirm all connections are tight, with no looseness or short circuits

Check that the terminal screw torque meets the requirements

Verify the phase sequence is correct (L1-L2-L3 corresponding to motor rotation direction)

- No-load Test (Without connecting the load)

Turn on the control power supply and test the contactor’s closing and opening actions

Observe if the coil overheats or produces abnormal noise

Check if the auxiliary contacts operate correctly (measure with a multimeter if necessary)

- 負荷テスト

Ensure the main circuit power supply is disconnected and perform an inching test first

Gradually increase the load and monitor the contactor’s temperature rise (not exceeding 60K) and operating noise

Test the overload protection function (if an LR E relay is installed)

- Maintenance Recommendations

Regular Inspection (once a month):

Check if terminal connections are loose (especially in vibrating environments)

Inspect contact wear condition (if contact wear indicators are available)

Check if the arc chute is damaged

Monitor for abnormal operating temperatures

Cleaning and Maintenance:

Disconnect the power supply before cleaning dust; do not use solvents to clean internal circuits

Ensure ventilation channels are unobstructed

- トラブルシューティング

| Problem | 考えられる原因 | ソリューション |

| Contactor fails to close | No voltage/insufficient voltage at the coil | Check the control power supply and circuit connections |

| Coil damage | Replace the contactor | |

| Excessive operating noise | Contaminated/oxidized iron core contact surfaces | Clean the iron core contact surfaces |

| Unstable power supply voltage | Check power supply quality | |

| Overheating of contacts | Poor contact | Retighten the terminals (pay attention to the specified torque) |

| Excessive load current | Check if the load exceeds the rated value |

Ⅶ. まとめ

The key to the correct installation of the LC1E180M5N contactor lies in: safe power-off, proper fixing, secure wiring and comprehensive testing. Following this guide not only ensures the reliable operation of the equipment but also extends its service life. インストール後, please keep the product label and installation records for future maintenance and inspection.

注記: This guide applies to the Schneider LC1E180M5N contactor and other models in the same series (LC1E120-LC1E630).

コンタクタ,サーキットブレーカー,ソーラーインバーター,電気メーター,太陽電池

コンタクタ,サーキットブレーカー,ソーラーインバーター,電気メーター,太陽電池

NH42-63-318x560.png)