ABB ACS355 series general machinery drive, 0.37 kW / 0.5 HP, single-phase 200–240 V input, IP20 protection, rated output current 2.4 UM. Suitable for speed control and energy-saving operation of small machinery.

1 Model Code Explanation

| Code Part | Significado |

| ACS355 | ABB general machinery drive series |

| 01E | Protection class IP20, for installation in enclosed electrical cabinets |

| 02A4 | Rated output current 2.4 UM |

| 2 | Single-phase 200–240 V AC (±10%), 50/60 Hz input |

2 Key Technical Data

| Item | Value |

| Rated power | 0.37 kW (0.5 HP) |

| Rated output current | 2.4 UM (at 40°C) |

| Input voltage / freqüência | Single-phase 200–240 V AC (±10%), 50/60 Hz |

| Output voltage / freqüência | Three-phase 0–240 V AC, 0–500 Hz |

| Protection class | IP20 (indoor cabinet installation) |

| Control method | Scalar control (V/f), built-in application macros |

| Overload capability | 150% de corrente nominal para 60 é; 180% para 2 é |

| Cooling method | Natural cooling |

| Dimensões (W×H×D) | 169×70×135 mm |

| Peso | Approx. 1.2 kg |

| Order code | 3AUA0000058166 |

| EMC performance | Built-in EMC filter, compliant with EN 61800-3 |

3 Key Features

3.1 Flexible Control

Predefined application macros: torque constante, fan/pump, PID control, etc..

Local/remote control switching via keypad, terminals or fieldbus

Built-in PID controller for closed-loop flow, pressure, etc..

3.2 Reliable Protection

Overcurrent, sobrecarga, sobretensão, subtensão, superaquecimento, phase loss protection

Motor over-temperature protection (requires external PTC)

Short-circuit and earth-fault protection

3.3 Operação fácil

Compatible control panel with ACS350/510/550 series

Parameter copy function for fast commissioning

MTBF > 100,000 hours for continuous operation

4 Aplicações Típicas

Small conveyors, packaging machinery

Fans, bombas (small HVAC systems)

Mixers, centrifuges and small processing machines

Automatic doors, roller shutters

Medical equipment, instrumentos de laboratório

Textile, printing and other light industrial machinery

5 Instalação & Commissioning Guidelines

5.1 Requisitos de instalação

Must be installed in an enclosed electrical cabinet

Temperatura ambiente: 0–40°C (derate 10% at 40–50°C)

Mount vertically, keep ≥ 100 mm clearance above and below for cooling

Avoid dust, oil, corrosive gases

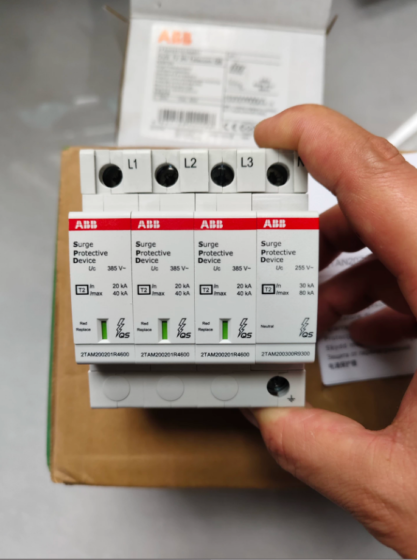

Input protection: 10 A MCCB (C-curve) or fuse recommended

5.2 Basic Commissioning Steps

- Pre-power check: Verify wiring (L1/N input, U/V/W output), terminal torque, proper earthing

- Parameter initialization

Group 99: set motor rated voltage, atual, poder, velocidade

Select application macro (Padrão, PID, etc.)

- Control configuration

Local control: via control panel

Controle remoto: via DI terminals or optional Modbus RTU

- Operation test

No-load test: run at 5–10 Hz, check rotation and stability

Load test: gradually apply load, verify current and temperature

Adjust acceleration/deceleration time (1–10 s recommended)

6 Cross-Brand Replacement Options (0.37 kW, 1-fase 220 V, IP20)

| Marca | Modelo | Key Matching Points |

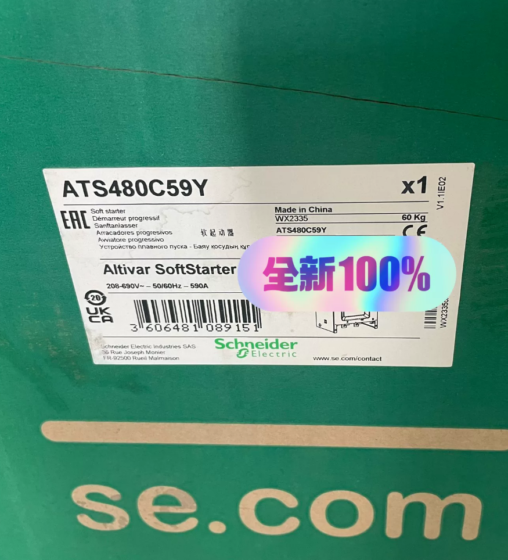

| Schneider | ATV12HU04M2 | 0.37 kW, 1-fase 220 V, IP20, similar size |

| Siemens | V20 6SL3210-5BB12-5UV1 | 0.37 kW, 1-fase 220 V, IP20, integrated EMC |

| Chint | NVF2-0.37/2 | 0.37 kW, 1-fase 220 V, IP20, economical alternative |

| ABB alternative | ACS150-01E-02A4-2 | Same power range, more compact design |

7 Selection & Maintenance Tips

7.1 Recommended Options

Braking function: optional braking resistor (75 Oh / 50 W recommended)

Comunicação: add RS485 module

Enhanced EMC: additional input EMC filter

7.2 Maintenance

Clean cooling channels every 6 meses

Check terminal torque annually

Avoid frequent starts/stops (≤ 20 times per day)

Storage temperature: -25°C a +60°C, dry environment

ABB ACS355-01E-02A4-2

Installation and Commissioning Manual

Overview: This manual provides complete instructions for safety, installation, wiring, parameter setting and commissioning of the ACS355-01E-02A4-2 drive (0.37 kW / 0.5 HP, single-phase 200–240 V) for general machinery speed control and energy saving.

1 Safety Instructions (Must Read)

1.1 Electrical Safety

Power-off procedure: Disconnect all power before installation, wiring or maintenance. Wait 5 minutes for internal capacitors to discharge.

Earthing: PE terminal must be reliably earthed (earth resistance ≤ 4 Oh)

Proteção contra sobrecorrente: Install 10 A MCCB (C-curve) or fuse on input side

Teste de isolamento: Only test motor cables; do NOT apply voltage to the drive itself

1.2 Mechanical Safety

Rotating parts (shaft, coupling, pulley) must be guarded

Mount vertically on solid surface to avoid vibration

Do not modify internal circuits or structures

1.3 Environmental Safety

Temperatura operacional: 0–40°C (derate 10% at 40–50°C)

Umidade: 5–95% RH, sem condensação

IP20: must be installed in enclosed cabinet

2 Product Overview and Model Identification

2.1 Model Explanation (ACS355-01E-02A4-2)

| Code | Significado |

| ACS355 | ABB general machinery drive series |

| 01E | IP20, cabinet-mounted |

| 02A4 | Rated output current 2.4 UM (40°C) |

| 2 | Single-phase 200–240 V AC, 50/60 Hz |

2.2 Core Specifications

| Item | Value |

| Rated power | 0.37 kW (0.5 HP) |

| Input voltage | Single-phase 200–240 V AC (±10%) |

| Output voltage | Three-phase 0–240 V AC |

| Output frequency | 0–500 Hz |

| Overload capacity | 150% para 60 é, 180% para 2 é |

| Cooling | Natural cooling |

| Dimensões (W×H×D) | 169×70×135 mm |

| Peso | Approx. 1.2 kg |

| Order code | 3AUA0000058166 |

3 Installation Procedure

3.1 Preparation

- Unpack and inspect drive for damage

- Choose well-ventilated, dust-free location inside cabinet

- Tools: chave Phillips (PH2), descascador de fios, ferramenta de crimpagem, multimeter, insulation tape

3.2 Mounting

- Mount vertically on flat metal plate

- Keep ≥ 100 mm above/below, ≥ 50 mm left/right clearance

- Fix with M4 screws, tightening torque: 1.2–1.5 N·m

4 Electrical Wiring

4.1 Terminal Description (ACS355-01E Series)

| Section | Terminal | Description | Wiring |

| Power Circuit | L1/N | Single-phase 200–240 V input | 1.5–2.5 mm² copper |

| Educação Física | Terra protetora | ≥ 2.5 mm² copper | |

| U/V/W | 3-phase output to motor | 1.5–2.5 mm² copper | |

| Circuito de Controle | DI1–DI3 | Digital inputs | 0.5–1.5 mm², máx. 50 eu |

| AI1/AI2 | Analog inputs (0–10 V / 0–20 mA) | Shielded twisted pair, máx. 100 eu | |

| AO1 | Analog output (0–20 mA) | Shielded twisted pair, máx. 100 eu | |

| +24V/GND | 24 V DC supply (máx. 100 mA) | 0.5–1.5 mm² | |

| RS485+/– | Modbus RTU | Shielded twisted pair, máx. 1000 eu |

4.2 Etapas de fiação

- Power wiring: L1/N to mains, PE to earth, U/V/W to motor

- Control wiring (Standard macro example):

DI1: Forward (FWD), DI2: Reverse (REV), DI3: Reset

AI1: Speed reference (0–10 V)

- Check torque, isolamento, and phase sequence

5 Parameter Settings

5.1 Keypad Functions

▶/■: Start / Stop

▲/▼: Adjust value

ENTER: Confirm

ESC: Back

LOC/REM: Local / Remote

5.2 Quick Motor Settings (Group 99)

| Parâmetro | Nome | Setting | Observação |

| 9901 | Language | Chinese / English | User choice |

| 9902 | Application macro | 1 (Padrão) | General use |

| 9903 | Motor type | 1 (Asynchronous) | Standard induction motor |

| 9904 | Motor rated power | 0.37 kW | From nameplate |

| 9905 | Motor rated voltage | 220/230/240 V | From nameplate |

| 9906 | Motor rated current | Motor nominal | Typically ~2.1 A |

| 9907 | Motor rated frequency | 50/60 Hz | From nameplate |

| 9908 | Motor rated speed | Motor nominal | ~1400–1450 rpm |

| 9909 | Number of motor poles | 4 | Standard for 0.37 kW |

| 9910 | Control mode | 1 (V/f) | Scalar control |

5.3 Common Application Parameters

| Group | Parâmetro | Nome | Recommended Value |

| 10 | 1001 | Max frequency | 50/60 Hz |

| 1002 | Min frequency | 0 Hz | |

| 20 | 2001 | Acceleration time | 3–10 s |

| 2002 | Deceleration time | 3–10 s | |

| 21 | 2101 | Acc/dec type | 1 (Linear) |

| 40 | 4001 | DI1 function | 1 (FWD) |

| 4002 | DI2 function | 2 (REV) | |

| 4003 | DI3 function | 9 (RESET) | |

| 50 | 5001 | AI1 type | 1 (0–10 V) |

| 5002 | AI1 minimum | 0% | |

| 5003 | AI1 maximum | 100% | |

| 16 | 1607 | Save parameters | 1 |

6 Commissioning Flow

6.1 Pre-Power Check

Correct power and control wiring

Motor and drive area clear

Cabinet ventilation OK

Input voltage: 200–240 V single-phase

6.2 First Power-Up

Close MCCB, display shows REM or LOC

Check for fault codes

Verify Group 99 motor parameters

6.3 Motor Identification (Opcional)

Definir 9910 = 2 (ID Run)

Press ENTER; drive runs motor briefly

Completed when shown COMPLETE

6.4 No-Load Test

Switch to LOCAL

Run at 5 Hz, check rotation

Increase to rated frequency, check noise and vibration

6.5 Load Test

Switch to REMOTE

Control speed via AI1

Check output current ≤ 2.4 UM

Adjust acc/dec to avoid overcurrent

Test protection functions

7 Solução de problemas

7.1 Common Fault Codes

| Fault | Description | Causa | Remedy |

| OVERCURRENT | Overcurrent | Motor overload, curto-circuito | Check load, motor, parameters |

| OVERVOLTAGE | Sobretensão | High mains, fast deceleration | Check voltage, increase dec time |

| UNDERVOLTAGE | Subtensão | Low supply, loose connection | Check mains and wiring |

| OVERTEMP | Overheating | High temp, blocked cooling | Improve ventilation, clean heatsink |

| MOTOR OVERLOAD | Motor overload | Excessive load | Check application, reduce load |

| FAULT RESET | Trip reset required | Fault occurred | Fix cause, reset via DI3 or keypad |

7.2 Typical Issues

| Symptom | Causa | Solução |

| Motor does not start | Wrong LOC/REM, missing DI signal | Check mode, wiring and parameters |

| Unstable speed | AI noise, poor parameters | Use shielded cable, adjust filtering |

| Communication failure | Wrong settings, bad wiring | Check Group 98, RS485, termination |

8 Maintenance

8.1 Manutenção de rotina

Clean cooling channels every 6 meses

Check terminal torque annually

Log operating current and temperature

8.2 Long-Term Storage

Temperatura: -25°C a +60°C

Dry, ventilated environment

Power on for 1 hour every 6 meses

9 Appendix: Options and Replacements

9.1 Recommended Options

Braking resistor: 100 Oh / 50 C

EMC filter

RS485 Modbus RTU module

Shielded cable for control wiring

9.2 Cross-Brand Alternatives (0.37 kW, 1-fase 220 V, IP20)

| Marca | Modelo | Matching Features |

| Schneider | ATV12HU04M2 | 0.37 kW, 1-fase 220 V, IP20 |

| Siemens | V20 6SL3210-5BB12-5UV1 | 0.37 kW, 1-fase 220 V, IP20 |

| Chint | NVF2-0.37/2 | 0.37 kW, 1-fase 220 V, IP20 |

| ABB | ACS150-01E-02A4-2 | Direct same-power replacement |

Manual Version: V1.0 (based on ABB official ACS355 manual, adapted for ACS355-01E-02A4-2)

Effective Date: February 2026

Copyright: ABB Group, Todos os direitos reservados

Contator,disjuntor,inversor solar,medidor elétrico,baterias solares

Contator,disjuntor,inversor solar,medidor elétrico,baterias solares

NH42-63-318x560.png)