Complete Model Interpretation

| Model Segment | Description |

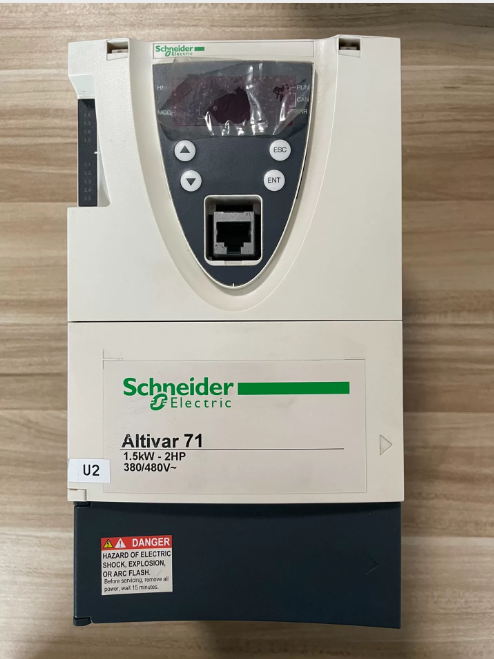

| ATV71 | Série de produits: Schneider Altivar 71 high-performance frequency converter, designed for complex, high-power mechanical equipment, primarily replacing the ATV58/68 series |

| H | Voltage Class: Three-phase 380~480V (50/60Hz) |

| C | Application Type: Constant Torque application, suitable for high-torque scenarios such as hoisting, lifting, and material handling |

| 28 | Power Code: Corresponding to a rated motor power of 280kW (some documents indicate compatibility with 315kW motors) |

| N4 | Standard Configuration: Built-in Class B EMC filter, IP20 protection class, no built-in braking unit |

| (Z) | Special Identifier: Indicates聽no built-in graphic display terminal, only equipped with a basic operation panel |

- Paramètres techniques de base

| Élément de paramètre | Valeur | Remarques |

| Rated Input Voltage | Three-phase 380~480V, 50/60Hz | Allowable fluctuation range: -15%~+10% |

| Rated Output Power | 280kW (compatible with 315kW motors) | Rated value for constant torque applications |

| Rated Output Current | 550UN | Continuous output current at 2.5kHz carrier frequency |

| Instantaneous Output Current | 825UN (pour 60 secondes) | 150% of rated current, suitable for heavy-duty starting |

| Maximum Output Frequency | 600Hz | Meets the control requirements of high-speed motors |

| Modes de contrôle | V/F open-loop, vector control (optional) | Supports multiple motor control algorithms for different application scenarios |

| Built-in Components | Class B EMC filter, basic operation panel | The Z version has no graphic display terminal; the VW3A1101 graphic terminal needs to be purchased separately |

| Classe de protection | IP20 | Suitable for installation inside electrical control cabinets |

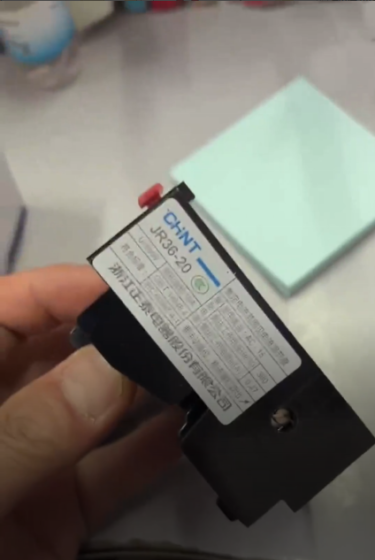

| Recommended Accessories | NSX630 circuit breaker, LC1F630 contactor are recommended | Ensure the safe operation of the electrical system |

III. Core Product Features

- High Torque Performance: Specifically designed for constant torque loads, with a starting torque of up to 150% of the rated torque, ideal for equipment requiring stable torque output such as cranes, elevators, and conveyor belts

- Flexible Control Functions: Prise en charge 8 preset speeds, PID regulator, and brake control logic to meet complex motion control requirements

- Integrated Communication Capability: Built-in Modbus and CANopen communication interfaces; support for industrial networks such as Profibus and Ethernet via expansion cards

- Comprehensive Protection Mechanism: Equipped with full protection functions including overcurrent, surtension, sous-tension, surchauffe, court-circuit, and ground fault protection, effectively safeguarding the frequency converter and motor

- Easy Maintenance: Built-in diagnostic functions for quick fault location; modular design facilitates repair and component replacement

- Application Scenarios and Compatible Equipment

- Main Application Fields:

Hoisting Machinery: Bridge cranes, tower cranes, port cranes, etc..

Lifting Equipment: Ascenseurs, escalators, mine hoists, etc..

Manutention des matériaux: Convoyeurs à bande, bucket elevators, screw conveyors, etc..

Other High-torque Equipment: Packaging machinery, woodworking machinery, high-inertia load equipment

- Not Suitable For:

Light-load or fan/pump type variable torque applications (the ATV71D series is recommended)

Unprotected outdoor installation (additional protective enclosures are required)

Scenarios requiring frequent braking (external braking units need to be configured separately)

- Key Selection and Usage Precautions

- Model Differentiation:

ATV71HC28N4: Equipped with a basic operation panel, no graphic terminal

ATV71HC28N4Z: Explicitly marked without a graphic terminal, with the same configuration as the above model

ATV71HD28N4: Constant torque version with a graphic terminal

- Exigences d'installation:

Must be installed inside an electrical control cabinet with IP20 protection class

Sufficient heat dissipation space must be reserved (more than 100mm on all sides: top, bottom, left and right)

An input reactor is recommended on the input side to reduce harmonic interference

- Accessory Purchase:

Graphic Display Terminal: VW3A1101 (applicable to models without the Z identifier)

Braking Unit: VW3A3520 (applicable to scenarios requiring frequent braking)

Communication Expansion Cards: VW3A3306 (Profibus DP), VW3A3310 (Ethernet), etc..

- Product Status Description

This model was discontinued on March 31, 2020. Schneider recommends the ATV930 series as a replacement product (model ATV930C28N4Z), which features more advanced control algorithms, higher energy efficiency, and more comprehensive communication functions.

Installation, Wiring Guide and Troubleshooting Manual for Schneider ATV71HC28N4(Z) Frequency Converter

- Key Installation Guidelines

1.1 Pre-installation Preparation

Safety Prerequisites: Only operated by certified electricians. Disconnect all power supplies before installation and wait for 15 minutes to allow the DC bus capacitors to discharge completely (tension < 45Vdc)

Exigences environnementales:

Température: -10°C à +40°C (derate by 1% for every 1°C increase above 40°C)

Humidité: 5%-95% sans condensation

Altitude: ≤1000m (derate by 1% for every 100m increase above 1000m)

Classe de protection: IP20 (cabinet installation), ensure good ventilation

Tool Preparation: Multimeter, 1000V mégohmmètre, clé dynamométrique, crimping tool, insulating tape

1.2 Installation mécanique

Méthode d'installation: Must be installed vertically, with 150mm heat dissipation space reserved on all sides (top, bottom, left and right)

Fixing Requirements: Secure with M12 bolts at a torque value of 50Nm to ensure stability and no vibration

Cooling System:

Equipped with built-in fan cooling; ensure air inlets are unobstructed

Clean dust in the air duct regularly (every 3 mois)

Install external cooling equipment when the ambient temperature exceeds 40°C

1.3 Connexion électrique (Core Steps)

| Connection Terminal | Fonction | Connection Requirements |

| R/L1, S/L2, T/L3 | Three-phase input power (380-480V) | 1. Connect to NSX630 circuit breaker (recommandé) |

| 2. Copper core cable with cross-sectional area ≥240mm² | ||

| 3. Torque value: 60Nm | ||

| U, V, W | Three-phase output (connected to motor) | 1. Copper core cable with cross-sectional area ≥240mm² |

| 2. Motor power ≤315kW | ||

| 3. Torque value: 60Nm | ||

| 4. Cable length ≤100m (no filter required) | ||

| PA, PC | DC bus terminals | 1. Connect to the built-in DC reactor |

| 2. External power supply is prohibited | ||

| PO, PC | Braking resistor terminals | 1. Connect only when rapid braking is required |

| 2. Braking resistor power ≥15kW | ||

| +24V, GND | Control power supply | 1. Connect to 24V DC power supply |

| 2. Copper core cable with cross-sectional area ≥2.5mm² | ||

| AI1-AI2 | Analog input | 1. Connected with shielded cable |

| 2. Shield layer grounded at one end | ||

| DI1-DI6 | Digital input | 1. Dry contact or PNP/NPN signal |

| 2. Copper core cable with cross-sectional area ≥1.5mm² | ||

| DO1-DO3 | Digital output | 1. Relay output (250VAC/30VDC) |

| 2. Maximum current: 5UN | ||

| PE | Protective grounding | 1. Copper core cable with cross-sectional area ≥95mm² |

| 2. Must be connected to the system grounding bar | ||

| 3. Torque value: 60Nm |

Connection Notes:

- Route input and output cables separately (distance ≥300mm) to avoid electromagnetic interference

- Use shielded cables for control circuits, with the shield layer grounded at one end (on the frequency converter side)

- Perform a tensile test on all terminal connections to ensure no looseness

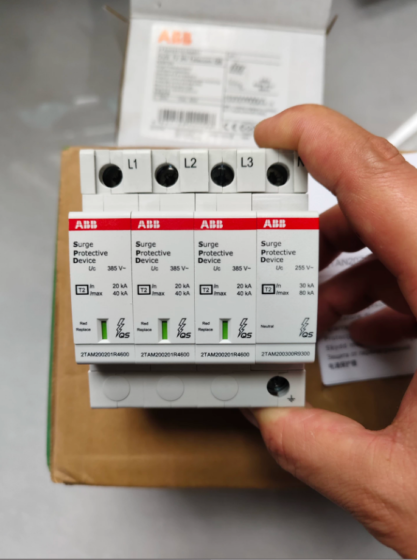

- Install a surge suppressor on the motor side (optional)

1.4 Control Circuit Wiring

Circuit de contrôle de base:

Connect the start (DI1), arrêt (DI2), and forward/reverse (DI3) bornes

Ensure the emergency stop circuit is independent of the frequency converter control

Communication Connection:

Modbus: Connect to RS485 terminals (+, -) with a baud rate of 9600-19200bps

Profibus: Install the optional VW3A3407 communication card

- Wiring Inspection and Commissioning Process

2.1 Wiring Inspection

- Insulation Test:

Insulation resistance between input/output terminals and ground ≥1MΩ (tested with 1000V megohmmeter)

Motor winding insulation resistance ≥1MΩ

- Continuity Test:

Check that there is no short circuit between input and output terminals

Verify normal continuity of control circuit terminals

- Paramétrage:

Restore factory settings (P0.01=1)

Set motor parameters (P1.01-P1.07): rated power, tension, actuel, fréquence

Set control mode (P2.01=0: V/F control; =1: vector control)

2.2 Commissioning Steps

- No-load Commissioning:

Disconnect the motor, start the frequency converter, and check for balanced output voltage

Test the frequency adjustment range (0-60Hz)

- Loaded Commissioning:

Connect the motor, set acceleration time (P4.01=10s) and deceleration time (P4.02=15s)

Gradually load up to 100% and check for normal current and temperature

Test overload capacity (150% of rated current for 60 secondes)

- Troubleshooting Manual

2.1 Fault Diagnosis Process

- Fault Identification: Record fault codes, operating status at the time of fault, and parameter settings

- Preliminary Inspection:

Power off and check for loose wiring and insulation damage

Inspect the cooling system and dust in the air duct

Measure power supply voltage and motor insulation

- Targeted Troubleshooting: Identify causes based on fault codes

- Solution Implementation: Repair or replace faulty components

- Verification Test: Conduct trial operation after fault elimination to confirm no abnormalities

2.2 Common Fault Codes and Solutions (Core Content)

| Fault Code | Fault Type | Causes possibles | Solutions |

| SCF1 | Motor Short Circuit | 1. Motor winding short circuit | 1. Test motor insulation with a megohmmeter |

| 2. Output cable damage | 2. Inspect cables and replace damaged parts | ||

| 3. IGBT module damage | 3. Run transistor test (Menu 1.10) | ||

| 4. Replace IGBT module | |||

| SCF2 | Ground Short Circuit | 1. Motor or cable grounding | 1. Check motor grounding resistance ≥1MΩ |

| 2. Internal grounding of frequency converter | 2. Test insulation between output terminals and ground | ||

| 3. Replace damaged components | |||

| OCF | Surintensité | 1. Sudden load change | 1. Extend acceleration time (P4.01) |

| 2. Excessively short acceleration time | 2. Inspect load and eliminate mechanical faults | ||

| 3. Incorrect motor parameters | 3. Reconfigure motor parameters | ||

| 4. Check current detection circuit | |||

| OLF | Motor Overload | 1. Load exceeds rated value | 1. Reduce load or operate at derated capacity |

| 2. Incorrect motor thermal protection parameters | 2. Set correct motor thermal current (ITH) | ||

| 3. Mauvaise dissipation de la chaleur | 3. Clean air duct and improve heat dissipation | ||

| 4. Inspect motor cooling fan | |||

| OHF | Frequency Converter Overheating | 1. Température ambiante trop élevée | 1. Improve ventilation and reduce ambient temperature |

| 2. Fan damage | 2. Inspect fan and replace damaged parts | ||

| 3. Air duct blockage | 3. Clean dust from air duct | ||

| 4. Check temperature sensor | |||

| USF | Sous-tension | 1. Input voltage below 340V | 1. Check grid voltage and install a voltage stabilizer if necessary |

| 2. Pre-charging resistor damage | 2. Inspect pre-charging circuit | ||

| 3. Power supply fluctuation | 3. Extend pre-charging time | ||

| 4. Replace damaged resistor | |||

| OSF | Surtension | 1. Input voltage above 480V | 1. Check grid voltage |

| 2. Excessively short deceleration time | 2. Extend deceleration time (P4.02) | ||

| 3. Braking unit fault | 3. Inspect braking unit and resistor | ||

| 4. Activate voltage suppression function | |||

| PHF | Input Phase Loss | 1. Phase loss in input power supply | 1. Check three-phase voltage balance |

| 2. Circuit breaker fault | 2. Inspect circuit breaker and contactor | ||

| 3. Input contactor fault | 3. Replace damaged components | ||

| 4. Check LCF parameter settings | |||

| EnF | Encoder Fault | 1. Loose encoder connection | 1. Inspect encoder wiring |

| 2. Encoder damage | 2. Test encoder signal | ||

| 3. Incorrect parameter settings | 3. Reconfigure encoder parameters | ||

| 4. Replace encoder |

2.3 Advanced Troubleshooting

Parameter Faults:

When “Invalid Setting” is displayed, press the ENT key twice to restore factory parameters

When parameters are corrupted, restore factory settings via P0.01=1

Communication Faults:

Check for loose communication cable and connectors

Confirm that baud rate and address settings match the host system

Test communication module and replace faulty modules

Hardware Faults:

Power Module Fault: Measure DC bus voltage (normal range: 540-600V)

Control Board Fault: Inspect indicator lights and replace control board if necessary

Driver Board Fault: Replace driver board and perform re-commissioning

III. Maintenance Schedule

| Cycle d'entretien | Maintenance Content | Remarques |

| Daily | Check operating status, parameters, and temperature | Record any abnormalities |

| Weekly | Clean surface dust and inspect cooling fans | Ensure fans are operating normally |

| Monthly | Check for loose wiring and cable insulation | Perform torque check on terminal connections |

| Quarterly | Clean dust in air duct and inspect insulation resistance | Use compressed air for dust cleaning |

| Annual | Comprehensive inspection and replacement of wearing parts (les fans, condensateurs) | Must be performed by professional personnel |

| Biennial | Capacitor performance test and full-machine commissioning | Replace capacitors if necessary |

Contacteur,disjoncteur,onduleur solaire,compteur électrique,batteries solaires

Contacteur,disjoncteur,onduleur solaire,compteur électrique,batteries solaires

NH42-63-318x560.png)