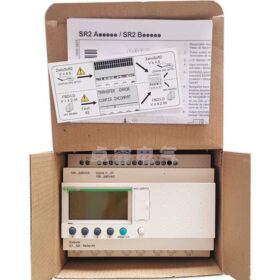

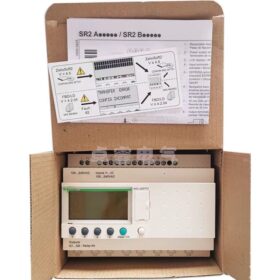

Complete Technical Guide for Schneider SR2A201FU Compact Smart Relay

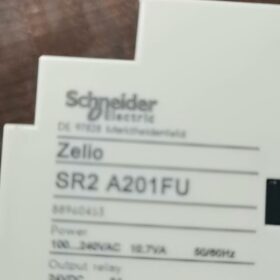

The Schneider SR2A201FU is a compact smart relay belonging to the Zelio Logic series. It integrates basic PLC functions with the advantages of relay control, and is suitable for logic control, remote management and monitoring of simple automation systems. The following is the complete technical parameters, recursos funcionais, application scenarios and model selection & replacement solutions.

- Core Product Overview

| Item | Parâmetro |

| Tipo de produto | Compact Smart Relay |

| Série | Zelio Logic SR2 |

| Configuração de E/S | 12 discrete inputs + 8 saídas de relé (20 I/O points in total) |

| Power Supply Voltage | 100~240V AC, 50/60Hz |

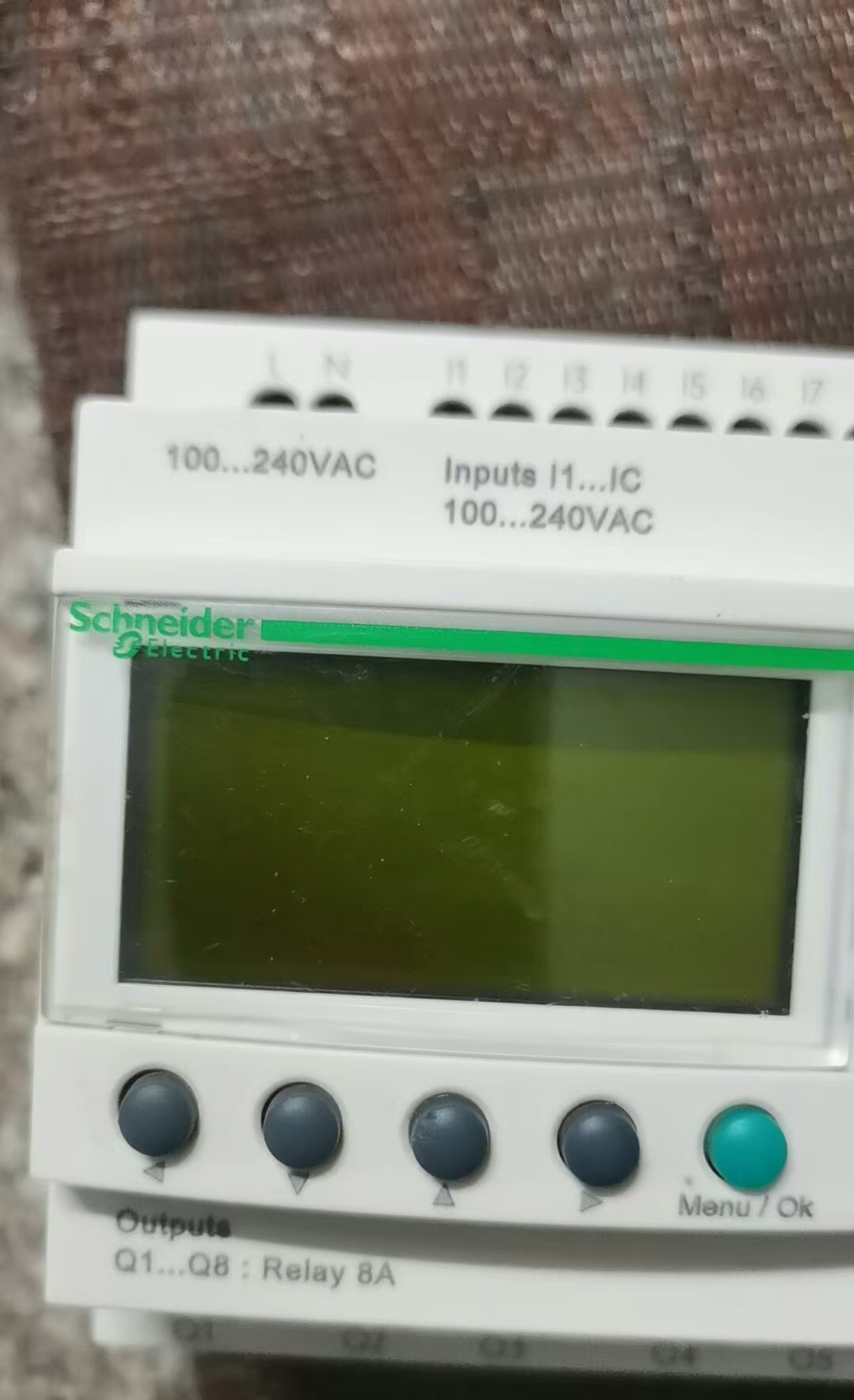

| Display Function | Equipped with LCD screen and navigation buttons |

| Clock Function | No built-in real-time clock |

| Método de montagem | 35mm standard DIN rail mounting |

| Classe de Proteção | IP20 (front panel), IP40 (overall) |

| Temperatura operacional | -20℃ ~ +55℃ |

| Temperatura de armazenamento | -40℃ ~ +70 ℃ |

| Warranty Period | 18 meses |

- Detailed Technical Parameters

(EU) Características de entrada

| Parâmetro | Specification |

| Number of Input Points | 12 discrete input points |

| Input Type | CC 24V (padrão), compatible with NPN/PNP signals |

| Input Current | Approximately 7mA per point |

| Tempo de resposta | ≤10ms |

| Isolation Method | Photoelectric isolation, 2500V e |

(II) Características de saída

| Parâmetro | Specification |

| Number of Output Points | 8 relay output points |

| Contact Type | Normalmente aberto (NÃO), C-type contacts (opcional) |

| Corrente nominal | Maximum 8A per point, for AC-1 category loads |

| Tensão nominal | Maximum 250V AC / 30V DC |

| Mechanical Service Life | ≥10 million operations |

| Electrical Service Life | ≥100.000 operações (at rated load) |

| Surge Protection | Built-in RC snubber circuit |

(III) Funções de controle

| Função | Specification |

| Programming Method | Ladder Diagram, supports 0~240 logic lines |

| Built-in Function Blocks | 16 timers, 16 counters, shift registers, comparators, etc.. |

| Memory | Built-in EEPROM flash memory, data retention up to 10 years |

| Communication Interface | Supports USB/Bluetooth communication expansion via SR2USB01 or SR2BTC01 module |

| Program Capacity | Can store multiple programs, supports program copying to other SR2 relays |

III. Principais recursos funcionais

- Integrated Design: Integrates PLC logic control and relay output, meeting small-to-medium-sized control requirements without additional expansion modules.

- Easy Programming: Supports ladder diagram programming. On-site editing, monitoring and fault diagnosis can be performed via the built-in LCD screen and navigation buttons, eliminating the need for a dedicated programmer.

- Flexible Adaptability: Wide voltage power supply (100~240V AC) is compatible with power grids worldwide, and DC 24V input is compatible with industrial sensor signals.

- Reliable and Durable: Industrial-grade design with strong anti-electromagnetic interference capability, adequado para ambientes industriais agressivos.

- Data Security: Built-in EEPROM memory ensures no program or data loss after power failure, with a backup cycle of up to 10 years.

- Cost Optimization: Replaces traditional relay control cabinets, reduces wiring complexity, and lowers maintenance costs and potential fault points.

- Cenários típicos de aplicação

- Motor Control: Start-stop, forward-reverse rotation, star-delta reduced-voltage starting and other self-locking and interlocking control for single/three-phase motors.

- Pump and Valve Systems: Logic control and protection for water supply and drainage, hydraulic and pneumatic systems.

- HVAC Control: Interlocking control of temperature/pressure/flow for fans, compressors and air conditioning systems.

- Lighting Management: Timed lighting, zoning control and energy-saving management for industrial plants and commercial buildings.

- Equipment Interlocking: Sequence control, counting, time delay and interlocking protection for simple processes in production lines.

- Remote Monitoring: Realize remote monitoring and control of equipment operating status through communication modules.

- Programming and Commissioning Methods

- On-site Programming: Directly perform logic editing, parameter setting and fault diagnosis via the built-in LCD screen and navigation buttons.

- Software Programming: Use the Zelio Soft dedicated programming software (including Discovery Package learning version), which supports ladder diagram editing, simulation and program upload/download.

- Communication Expansion:

SR2USB01: USB communication module, enabling high-speed data transmission between PC and relay.

SR2BTC01: Bluetooth communication module, supporting wireless programming and monitoring.

- Diagnóstico de falhas: The LCD screen displays real-time I/O status, timer/counter values and fault codes, facilitating quick problem location.

- Model Selection, Replacement and Cross-brand Alternatives

(EU) Schneider Same-series Alternatives

| Modelo | Differences | Cenários de aplicação |

| SR2A101FU | No LCD screen | Cost-sensitive fixed control scenarios that do not require on-site programming |

| SR2A201FW | With real-time clock | Applications requiring timing control and time recording |

| SR2B201FU | 8 inputs + 4 saídas de relé | Scenarios with fewer I/O point requirements |

| SR2B201FW | 8 inputs + 4 saídas de relé + clock | Simple timing control scenarios |

(II) Cross-brand Alternative Solutions

| Marca | Modelo | Compatibilidade | Observações |

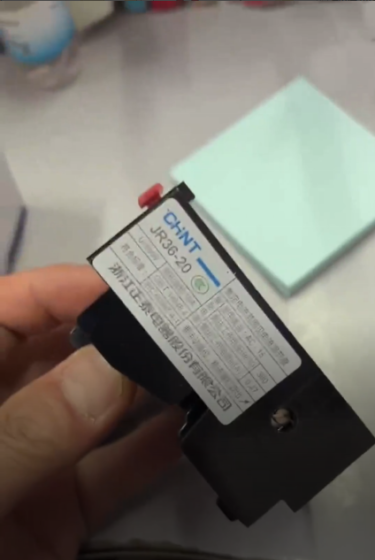

| Chint | NX-SR Series Smart Relays | ★★★☆☆ | Similar functions, I/O points need to be matched accordingly |

| Delicioso | CDSR Series | ★★★☆☆ | Compatible with basic logic control functions |

| Omron | CP1E Series Micro PLC | ★★★★☆ | More abundant functions, programming software needs to be adapted |

| Siemens | LOGO! Série | ★★★★☆ | Same type of compact smart relay with different communication protocols |

VII. Installation and Wiring Key Points

- Local de instalação: Mount on 35mm standard DIN rail, reserve ≥50mm heat dissipation space, and avoid high temperature, umidade, dust and strong electromagnetic interference environments.

- Power Supply Wiring: Connect L/N to 100~240V AC power supply, and ensure the PE terminal is reliably grounded.

- Input Wiring:

Connect the common terminal (COM) to the negative pole of DC 24V.

Connect input points to the positive pole of sensor signals, with a response time ≤10ms.

- Output Wiring:

O terminal comum (COM) of relay outputs can be connected to AC 220V or DC 24V power supply.

Maximum load of 8A per point; para cargas indutivas, a freewheeling diode (DC) or RC snubber circuit (AC) must be connected in parallel.

- Communication Wiring: Realize USB/Bluetooth communication through expansion modules, with communication cable length ≤5m.

VIII. Solução de problemas de falhas comuns

| Fenômeno de falha | Possíveis causas | Troubleshooting Methods |

| Power indicator not lit | Poor power connection/abnormal voltage/damaged power module | Check power wiring and voltage, replace the power module |

| No input response | Abnormal input signal/wiring error/damaged input point | Measure input signal, check wiring, replace the input point |

| No output action | Damaged output point/load short circuit/logic error | Check load and wiring, simulate and test logic with Zelio Soft |

| Program loss | EEPROM fault/abnormal power failure | Check power stability, re-download the program |

| Communication failure | Poor connection of communication module/incorrect software settings | Check module connection, confirm communication parameter matching |

- Safety and Maintenance Suggestions

- Safe Operation: Programming and wiring must be performed under power-off conditions to avoid electric shock risks.

- Manutenção regular:

Inspect wiring terminals for looseness and clean dust on the equipment surface every quarter.

Test I/O point response and relay contact reliability every year.

- Program Backup: Regularly back up programs via Zelio Soft software to prevent data loss.

- Spare Parts Reserve: It is recommended to reserve spare relays of the same model for critical applications to shorten fault downtime.

Contator,disjuntor,inversor solar,medidor elétrico,baterias solares

Contator,disjuntor,inversor solar,medidor elétrico,baterias solares

NH42-63-318x560.png)